Bolts are torqued during the final assembly of a propeller.Hartzell Propeller is a true American success story. As many manufacturers worldwide are going through tough times, Hartzell is continuing a long tradition.

Bolts are torqued during the final assembly of a propeller.Hartzell Propeller is a true American success story. As many manufacturers worldwide are going through tough times, Hartzell is continuing a long tradition.

In 1875, John T. Hartzell began the company as a sawmill, cutting general hardwoods. However, things took a very significant turn when in 1917, with a strong interest in aviation and the encouragement of none other than aviation pioneer Orville Wright, Robert N. Hartzell, John’s son, left the University of Cincinnati to start the manufacture of aircraft propellers at his father’s company. Today, Hartzell constant-speed propellers are manufactured for the widest range of aircraft in the industry.

When recently asked about the company’s slogan, Burt Mattice, Hartzell’s director of quality responded, “Built on Honor is not just our motto, it is our way of life. It is our foundation for assuring we have the highest quality in our processes, we hire the best of the best employees, and everything we do is with pride and the utmost care and respect.”

Serving private, commercial and military customers, Hartzell makes constant-speed propellers, governors and deicing systems for propellers. Roughly 18,000 Hartzell parts and systems are used on more than 2,000 makes and models of aircraft.

“We believe that products must be designed, made and shipped right the first time and every time, at the lowest total cost. This is accomplished in part by having an intense focus on identifying, controlling and ultimately eliminating the source of variation in our processes,” Mattice states. “It is this focus on variation reduction that allows our inspection procedures to concentrate on verifying that our processes are statistically under control.

“Our design characteristics are defined on our drawings and in our specifications. It is these characteristics that provide a framework for the types of features that need to be verified prior to acceptance of the product. With all of this information known, we can then determine an acceptable inspection method for the feature that needs verification using tools like process and gage capability studies.

“When we have products where contamination, dirt or surface finish defects are a concern, we primarily use a form of visual inspection to verify that the product is acceptable,” Mattice says. “When we have tight locations to inspect, such as small bores and blind holes, a visual inspect with a fiber optic flashlight may not be sufficient. Therefore, in that type of situation, we rely on using borescopes to aid in the visual inspection.” Hartzell exclusively uses Hawkeye Precision Borescopes, manufactured by Gradient Lens Corp.

Mattice explains, “For example, we inspect the propeller pitch change rods for damage and contamination to ensure it is acceptable prior to assembly. This component part is for our constant-speed propellers.” A constant speed propeller is one in which the propeller blade angle varies to maintain a constant engine rpm as set by the pilot for different phases in flight. To do that, oil comes from the engine oil system into the propeller governor, which senses engine speed and regulates the oil pressure to achieve the desired blade angle.

Borescopic video inspection of propeller balance hole“So that is one situation in which we use borescopes to aid in the visual inspection,” Mattice explains. “We use the Hawkeye borescopes exclusively because they are easily portable, dependable, accurate and very cost-efficient. We manufacture and service our products in multiple facilities, and we can just pick up the borescope systems and move them from building to building as needed. We primarily use rigid borescopes, 7" to 22" in length, with a 0º direction-of-view (DOV). The Hawkeyes can easily be changed to a 90º DOV by adding a mirror tube accessory. We also connect some borescopes to video systems for on-screen viewing and image capturing.”

Borescopic video inspection of propeller balance hole“So that is one situation in which we use borescopes to aid in the visual inspection,” Mattice explains. “We use the Hawkeye borescopes exclusively because they are easily portable, dependable, accurate and very cost-efficient. We manufacture and service our products in multiple facilities, and we can just pick up the borescope systems and move them from building to building as needed. We primarily use rigid borescopes, 7" to 22" in length, with a 0º direction-of-view (DOV). The Hawkeyes can easily be changed to a 90º DOV by adding a mirror tube accessory. We also connect some borescopes to video systems for on-screen viewing and image capturing.”

In the production of aircraft propellers, Hartzell uses various types of machines and tools. With aluminum propeller blades, for example, the blade shanks are turned to finished dimension on a CNC lathe. Then, high-speed, high-precision 5-axis CNC mills cut the airfoil shape. Inspected features include airfoil shape, leading edge alignment, face alignment, thickness at specified locations, width, blade angle, etc.

Hartzell strives to meet what they describe as a flexible approach to manufacturing. With more than 2,000 product applications, they want to make sure they can run small lot sizes and really meet the customer’s requirements – definitely not assembly line mass production. To meet those goals, Hartzell structures highly-efficient work cells – their manufacturing cell is dedicated to running specialized components and using standardized machines in order to move from machine to machine, depending on capacity and maintenance schedules. Hartzell can also make rapid changeovers and maintain quick set-up capability.

“We have the ability to make short production runs (10 parts to 15 parts), shut the process down, have quick changeovers and quick set ups to start running the next type of part,” Mattice says. Hartzell also maintains a complete inventory and tool control system to make sure they always have the tools available when they are needed.

“We know the key to our success is rooted in our highly-skilled workforce, so we are always striving to make sure that there are open lines of communication and that the only bad idea is the one that you did not bring up. When you couple this with always having the latest technology and a relentless pursuit of continuous improvement, you have a recipe for success,” Mattice adds.

Hartzell maintains a client list that includes Air Tractor, Cirrus Aircraft, Daher-Socata Hawker Beechcraft, Pilatus, Piper, Raisbeck Engineering, RAM Aircraft and Van’s.

“You can buy the best machines and processes in the world, but at the end of the day superior quality ultimately comes down to making sure you have the right people in the right places, using the right technology at the right time,” Mattice concludes.

Hartzell Propellers

Piqua, Ohio

hartzellprop.com

Gradient Lens Corp.

Rochester, NY

gradientlens.com

Explore the November December 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

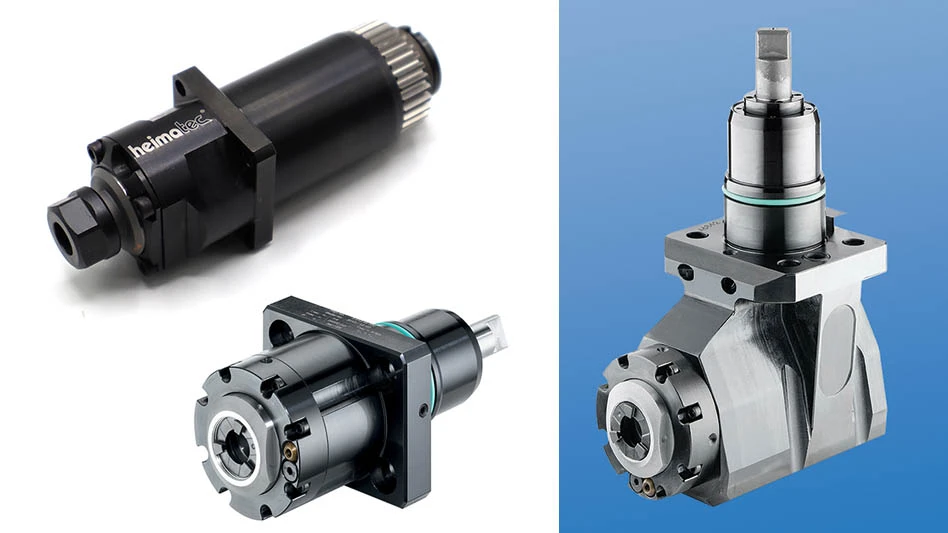

- Making workholding work for you

- CAE to deliver full flight simulator to Embraer-CAE Training Services

- Website helps users quickly search, evaluate, specify machine tool accessories

- HondaJet Elite II Emergency Autoland is FAA certified

- Software for creating measurement programs updated

- Nidec Aerospace establishes Atlanta hub to accelerate electric propulsion innovation

- Brochure for high-precision motion control, nanopositioning automation, piezo solutions

- Forecast 2026 Webinar