Purchasing an automation system with monitoring and feedback functionality will help support long-term goals and continuous improvement efforts.

Dave Walton, director of engineering at Makino discusses an Automation Implementation Blueprint.

Successful implementations of manufacturing automation projects start with a clear understanding of desired goals, objectives, requirements and potential short- and long-term challenges. As with any significant investment, including automation, conducting discovery is critical to defining the scope of a project and identifying solution(s) that will be within budget, produced and installed on schedule and have the greatest return on investment. Automation solutions are best when scalable and manageable and have defined operator functions, part processing requirements, and operating environments. Purchasing an automation system with monitoring and feedback functionality will help support long-term goals and continuous improvement efforts.

Latest from Aerospace Manufacturing and Design

- OMA and NIMS partner to launch semiconductor technician credentials

- Analysis, trends, and forecasts for the future of additive manufacturing

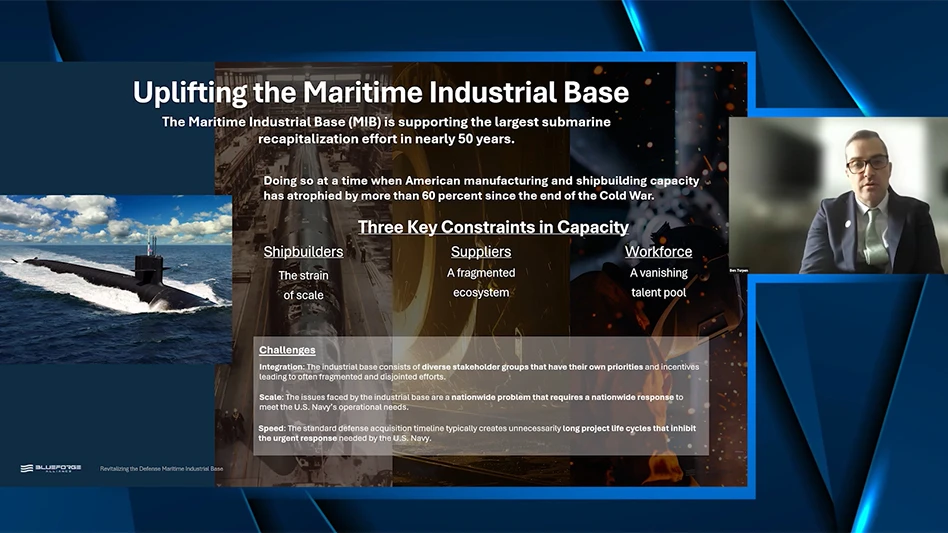

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Blaser Swisslube, NIDEC Machine Tool America partner

- Extrusion crosshead combines concentricity adjustment, fastener-free assembly

- Vertical Aerospace unveils Valo eVTOL aircraft

- 3xD pilot step drill

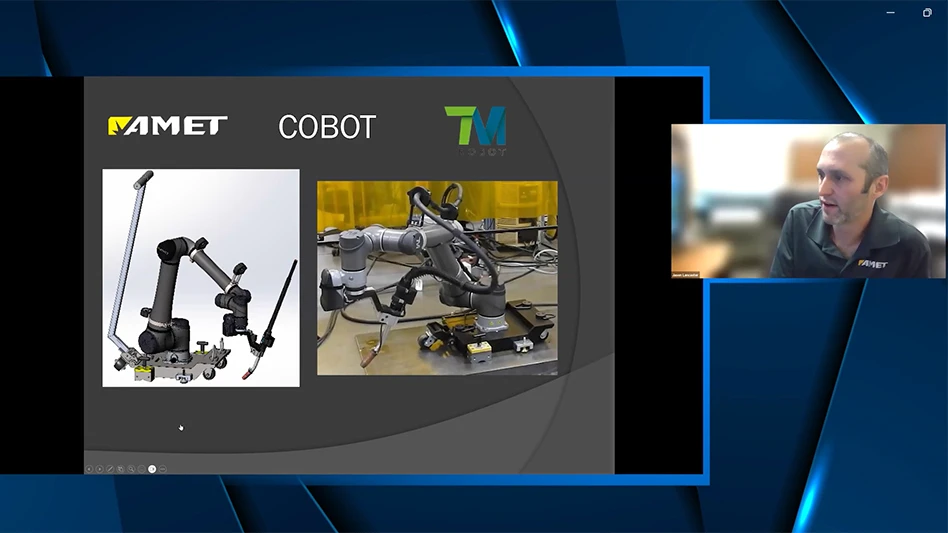

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.