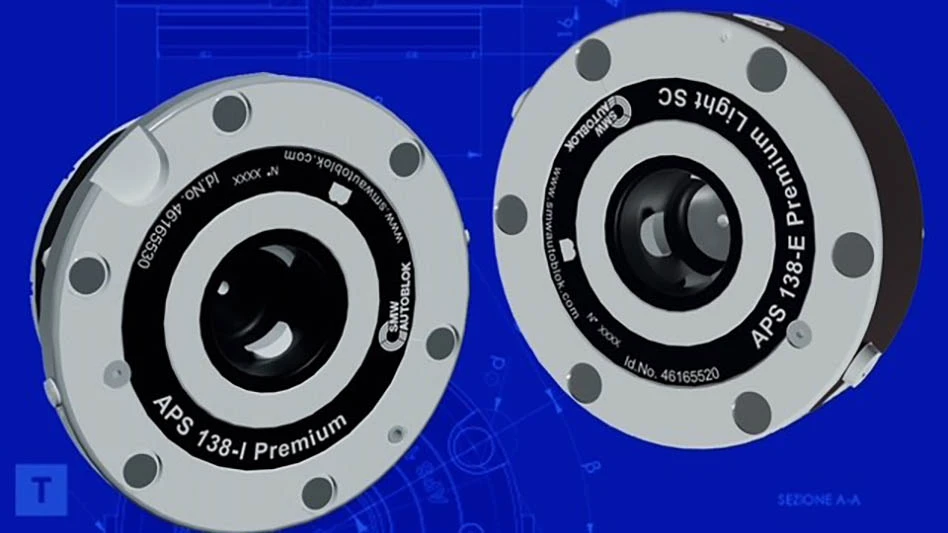

Photo credit: SMW Autoblok

SMW Autoblok, a world leader in the design and manufacture of rotational chucks, stationary workholding, tooling, and custom engineered solutions for the machine tool industry introduces its next-generation APS 138‑E and APS 138‑I zero-point clamping modules, engineered to deliver <0.005mm repeatability, maximum rigidity, and universal interface compatibility across nearly all zero-point systems currently in the market.

The APS 138 series enable high-speed part changeover, full automation support, and superior machining accuracy across turning, milling, and grinding operations.

With the APS 138-E for external mounting and APS 138-I for integrated, built-in applications, both modules provide the same mechanical performance characteristics: a three-jaw clamping design, spring-actuated locking, and TURBO-assisted pull-down forces up to 26kN. Holding force reaches 75kN using standard ISO 4762-12.9 screws, and modules can be unlocked pneumatically at 6 bar via side or bottom actuation.

"This platform is designed as a direct-fit alternative to other zero-point systems on the market, shops don’t have to reconfigure their workholding systems to gain a boost in precision and speed," said Larry Robbins, President and CEO at SMW Autoblok USA.

Engineered for integration

The APS system serves as a universal interface between the machine tool, clamping device, and workpiece. It requires no traditional fixturing methods and is ideal for pallet automation and modular setup.

All APS modules are Proofline sealed, fully protected against coolant, corrosion, and swarf. An integrated air purge system for cleaning and locating surfaces is standard, helping maintain chip-free mating surfaces, essential for automation and high-tolerance part handling. Select models support pneumatic stroke control (SC) for real-time monitoring and feedback during robotic load/unload cycles.

The three-jaw system includes 3 clamping slides, providing higher pull-down forces and eliminating the need for special setups during multi-directional milling operations. The APS 138 series is fully suitable for automation, supporting both manual and robotic workflows without compromising speed or accuracy.

Key Technical Features:

- < 0.005mm repeatability across changeovers

- Turbo-enhanced pull-down and spring-locked holding for rigid clamping

- 3 clamping slides for higher pull-down forces and simplified multi-directional milling setups

- Universal fit for most industry-standard zero-point geometries

- Standard integrated air purge system for clean, repeatable interfaces

- Suitable for full automation, including robotic loading/unloading

- Hardened steel construction for long service life in production environments

- 100% modular design for flexible machine tool adaptation

Whether applied externally or internally, the APS 138 series is suited for high-speed, automated part changeover with no compromise on accuracy, uptime, or system flexibility.

For detailed specs, CAD files, or demo requests, visit: https://www.smwautoblok.com/us/en/, or email info@smwautoblok.com.