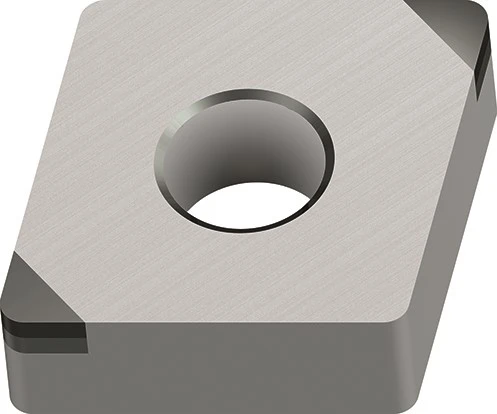

Walter introduced the CBN grade WBH30 for hard turning in interrupted cuts. This new grade, with a reliable and high-performance substrate exhibits excellent toughness primarily because of its good distribution of mixed CBN grain sizes. The new grade offers chemical stability derived from a TiN binder preventing crater and flank face wear. It also provides wear resistance in hardened steels due to the 65% CBN content, and higher feeds.

Surface quality and stability can be improved with advanced wiper geometry option. Walter offers the new WBH30 CBN grade inserts with and without MW wiper geometry, and with a negative T-land chamfer for excellent strength in interrupted cuts.

WBH30 is the latest addition to the Walter family of CBN grades engineered to tackle the toughest machining challenges. These include grades WBH10C, WBH10, and WBH20 for turning of hardened steel up to 65 HRC. These grades provide users with benefits such as high-quality surface finish and long tool life. Walter has also created WBK20 and WBK30, CBN grades that bring higher levels of productivity and reliability to the machining of cast iron and certain specific applications in hardened steel, among other benefits.

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling, and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Waukesha, WI, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico, and Brazil.