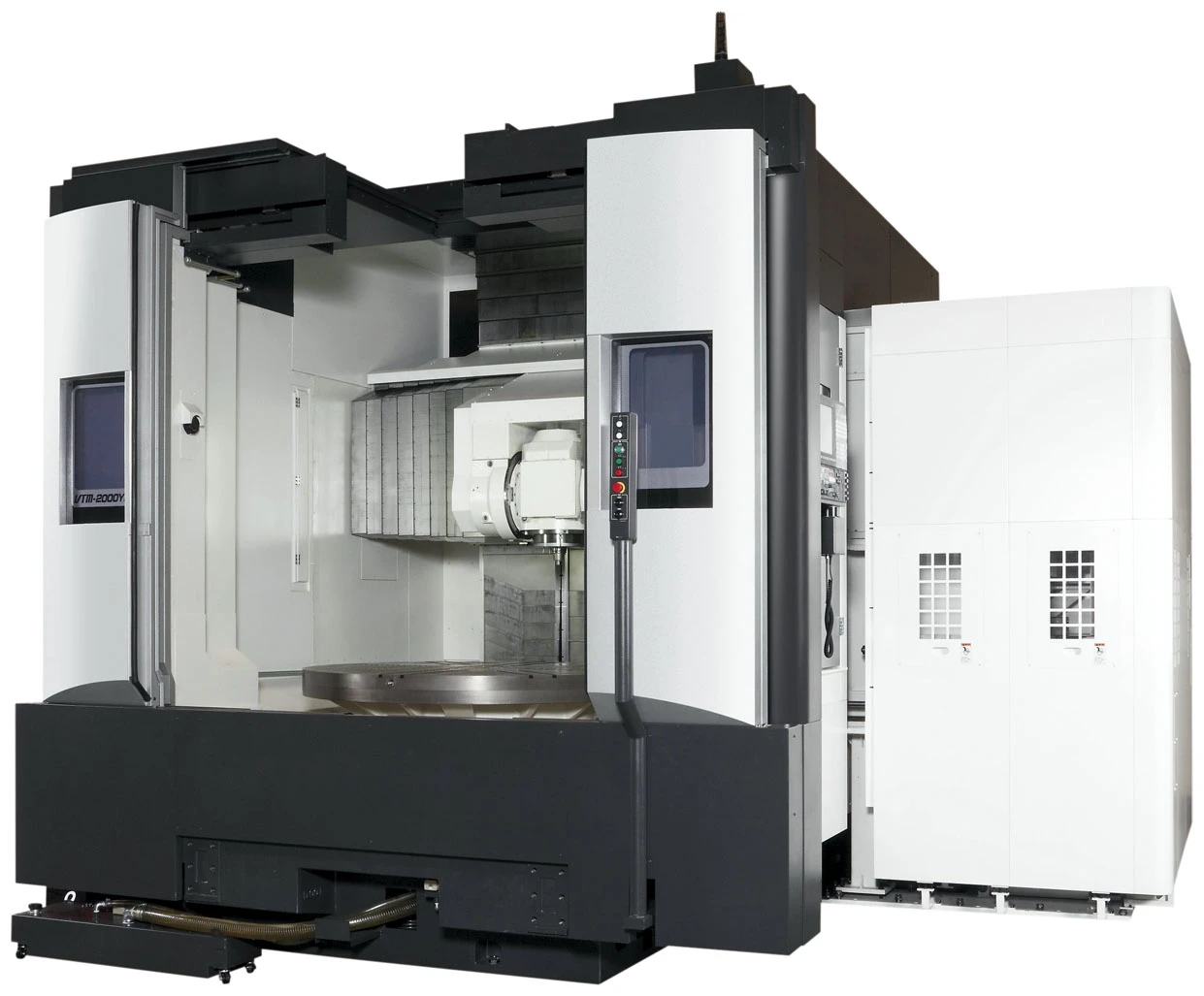

At IMTS 2014 Okuma will introduce its new VTM-2000YB multitasking CNC turning center, which provides heavy-duty construction for large parts machining. The extreme rigidity and powerful cutting capabilities of this machine makes it ideal for machining large diameter workpieces, such as those in the aerospace industry. The vertical architecture offers the advantage of “natural” part handling and excellent chip fall, while taking up minimum floor space. At IMTS this machine will be providing a large work envelope demonstration on a fan hub and engine case, featuring Super-NURBS and tooling from Sandvik, a member of Partners in THINC.

The VTM-2000YB takes the successful concept of the VTM-200YB and advances the design to increase rigidity, power, B axis range, speed and accuracy. It utilizes Okuma’s Thermo-Friendly Concept to enhance thermal stability, and has powerful turning and milling capabilities with .001° B and C axes. This CNC turning center has 1.6 meter of Y axis travel, combines powerful turning and milling functions for large parts in the same machine and includes a 36 tool ATC for tool changing.

Key Specs of VTM-2000YB CNC Turning Center

Max Turning Diameter mm (in) Ø 2,000 (Ø 78.74")

Spindle Nose Type 380mm Flat Nose

Speed Range min?¹ 4~200

Power 30 min kW (hp) 30 (40)

Power cont. kW (hp) 22 (30)

Rapid Traverse (X/Y/Z) m (in)/min 32/32/32 (1,260/1,260/1,260)Power 30 min

Rapid Traverse (B/C) RPM 19.5/20

For more information on Okuma’s VTM-2000YB visit the Okuma Booth S-8500 at IMTS 2014.