Turning and Grinding Machines

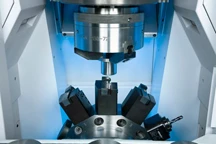

The VL 2 P and VL 5i vertical turning machines, and the VSC 400 DDS turning and grinding center are designed with integrated pick-up automation, a machine body made of polymer concrete, as well as the vertical design which ensures perfect chip flow conditions.

Workpieces up to 100mm in diameter can be machined in full on the innovative VL 2 P, a two-spindle turning machine that allows one workpiece to be machined while the second spindle automatically loads itself using the pick-up method. This means that the next raw part is immediately ready for machining, resulting in extremely short chip-to-chip times. The VL 5i turning machine can completely machine workpieces of up to 250mm in diameter in a single clamping operation. In addition to the powerful pick-up working spindle with a rating of 28 kW and a torque of 300 Nm, the machine also has an automation system with a revolving belt which contains drag frames.

The VSC 400 DDS vertical grinding and turning center combines a range of processes and guarantees extremely cost-effective processes in the production of complex chuck parts with a diameter of up to 400mm. Within a single clamping operation, the center can complete scroll-free turning and hard turning as well as subsequent grinding processes. Grinding is only used where quality and process reliability demands it. The center can also be fitted with drilling tools or hardening modules to suit the required machining task. Even measuring tasks can be integrated.

EMAG L.L.C.

38800 Grand River Avenue

Farmington Hills, MI 48335

Phone: (248) 477-7440

Fax: (248) 477-7784

E-mail: abrandemihl@emag.com

www.emag.com