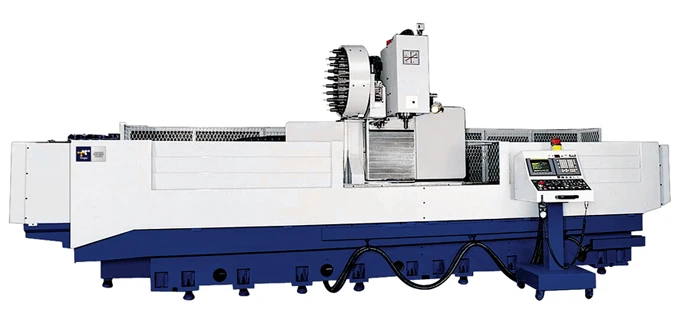

This heavy duty, yet quick CNC milling and tapping center is designed specifically for aerospace airframe component production. The machine is designed to machine either long narrow workpieces or to have the work table sectioned into a variety of safe work zones for multiple set-ups. The QVM-610A 2000-5000 machine is a traveling column type design where the worktable is stationary.It features a Meehanite cast iron frame and linear slideways for fast, precise movement. Most importantly is the X axis travel capability of up to 196”. Due to this long X axis travel, a 63mm (2.5”) diameter ballscrew is used on X along with 40mm (1.57”) diameter ballscrews on the Y and Z axes. All ballscrews are class 3 with a double nut pre-loaded design allowing amazing rapid traverse rate of 944 inches per minute in Y and Z axes. The ABS (Absolute Pulse Coder) servo system does not require zero return. The machine can be started anytime from any position, saving non-productive time. Standard twin screw type chip conveyors on each side of the table and a caterpillar style at the end of the machine provides efficient and automated chip removal.

A standard 24 station high speed arm type ATC provides fast, reliable tool changes. The 8,000rpm spindle provides rigid tap speeds up to 4,000rpm.

The Fanuc OiM-D control is standard to provide you with reliable state-of-the-art controllers and the latest in servo and spindle technology. The optional Fanuc 18iM-B is capable of handling the most demanding high speed machining applications and is available with a full complement of high speed machining options for mold detail high speed 3-D machining.