MTS Systems Corp. Sensors Division's C-Series sensor has been designed into a surgical tool used in a non-invasive treatment for Degenerative Disc Disease (DDD). After initial versions of the equipment demonstrated significant control issues, Disc Dynamics (Eden Prairie, MN), the developers of the technique and tools, and Devicix (Chaska, MN), a medical design firm, designed the C-Series linear sensors into a microprocessor-based solution that has allowed the procedure and equipment to be approved for use in Europe and to undergo clinical trials in the United States.

"Designed for use in higher-volume OEM products such as medical devices, small cutting/fastening/forming tools, and various consumer products, the C-Series is the smallest magnetostrictive sensor available, as well as the lowest cost sensor, making it useful for high volume projects with constrained space and budgets," said Jesse Russell, MTS Temposonics Commercial Product Marketing Manager. "Its small size, enhanced sensitivity and automatic adjustment features make it ideal for this application as well."

The procedure, termed the Dascor Disc Arthroplasty System, is minimally invasive, so the patient experiences only a small incision for the surgeon to gain access to the affected area. The nucleus material of a disc is removed and replaced with an artificial nucleus that restores the proper gap height between the vertebrae with a patient-specific implant.

Initial versions of the surgical tool used to install the artificial nucleus delivered the two-part polymer to the site pneumatically and proved to have control issues that made it difficult to ensure the desired amount of polymer was injected.

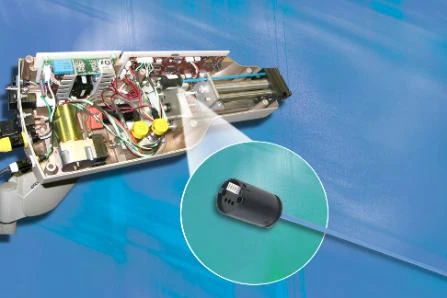

The technique's developers, Disc Dynamics, worked with Devicix to integrate the procedural requirements into a viable surgical tool that solved these problems and could be easily operated by physicians and trained technicians. Over the short design time of two years, Devicix integrated software, electrical and mechanical disciplines into a microprocessor-based tool that allows closed loop control of polymer injection via feedback from linear position and pressure sensors. Instead of a pneumatic system, the Dascor System now uses a motor driving a ball screw monitored by a C-Series Temposonics linear position sensor to deliver an accurately measured quantity of the two-part polymer.

"Temposonics was chosen because of its no-wear nature, no drift-over-time, no required calibration, and ease of connection to the mechanical system," said Russell.

Forward and rearward travel limits are calibrated from the C-Series position feedback, eliminating the need for redundant limit switches. Originally installed to provide power-up position information to calibrate the position of rotary incremental encoders, the absolute output of the C-Series proved so resolute and reliable that the encoders were eliminated. Calculated required volume from a CT scan is compared with filling volume in the balloon, calculated from the sensor?s feedback, ensuring the correct final size while preventing the balloon from becoming too large.

At 36mm, the C-Series head is 45 percent smaller than its predecessors, and the 4mm sensor shaft diameter, 18mm dead zone and 21mm null zone, all are at least 50 percent smaller. This improves the overall length-to-active zone ratio, which is key in smaller device implementations common to medical desktop size machines.

The same functionality that made the C-Series the optimal solution for Disc Dynamics and Devicix, as well as for medical applications such as infusion devices, x-y positioners, medical beds, grippers, filling mechanisms, and dispensing tool applications, makes it the ideal option in other industries such as professional tools, patient therapy and exercise machines, business machines and other high volume light industrial/commercial products.