Photo credit: Smalley

Smalley is launching the Nestawave, a breakthrough in spring design that combines the space-saving deflection of a Crest-to-Crest wave spring with the high-force output of a Spirawave nested spring. Manufactured from a single continuous wire, this design offers consistent load properties and enhanced performance.

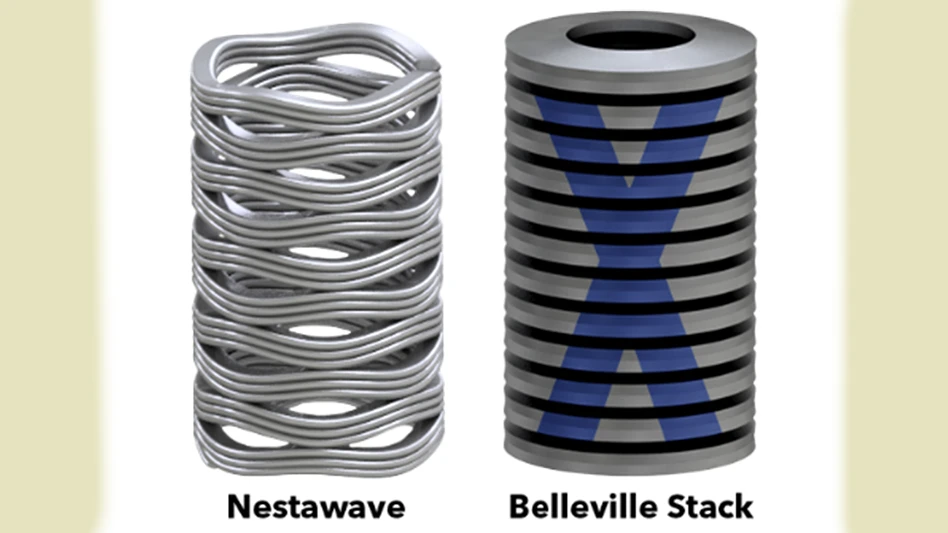

Nestawave springs are engineered for applications requiring high load capacity and significant travel within compact spaces. By nesting multiple turns of flat wire in a Crest-to-Crest configuration, Smalley has created a single spring that delivers force and flexibility. This design is ideal for replacing stacks of Belleville washers, helping to reduce part count, labor, and installation errors. In one application, Smalley engineers helped a customer streamline their design by replacing a stack of 24 Belleville washers with a Nestawave spring.

These springs are well-suited for use in actuators, bearing preloads, compressors, valves, and other high-performance components. They are commonly applied in industries such as aerospace and oil and gas, where reliability and precision are critical.

Product samples of the Nestawave are now available online. To learn more or request a design consultation, visit smalley.com/nestawave.

Building on its legacy of precision and performance, Smalley continues to push innovation in spring engineering with solutions that meet evolving industry demands. Nestawave springs are available exclusively as custom solutions, tailored to meet the specific requirements of each application.