Geomagic, a worldwide software and services company, announces the release of Geomagic Qualify 9 and the Geomagic Blade extension, the digital inspection solution that helps manufacturing organizations meet quality standards and improve the manufacturing process.

Geomagic Qualify 9 offers a highly efficient, accurate, repeatable and cost-effective way to compare as-built to as-designed parts and machinery. When combined with the new Geomagic Blade extension, it provides a powerful tool for digital inspection in the turbomachinery industry for the analysis of rotors, stators, impellers and internal blade features.

New features in Geomagic Qualify 9 include support for multiple coordinate systems; advanced 2D dimensioning features; direct access to CAD geometry; and line profiles, which improve the clarity, quality, speed and interpretation of inspection reporting and analysis. Other benefits of the software's new version are faster workflow and cleaner models.

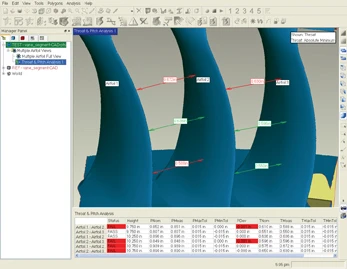

Geomagic Blade adds multi-vane analysis for users in the turbomachinery industry, including aerospace, power generation equipment and automotive manufacturing. Users can analyze and report on dimensions related to turbine segments such as minimum opening and minimum distance from blade to blade. The software also dramatically simplifies the analysis of complicated geometries found inside a blade for cooling or flow purposes.

Geomagic Qualify 9 analysis reliability is certified by PTB, ANFIA and major turbomachinery and automotive manufacturers. The software offers direct plug-ins with popular digital scanning devices such as arm-scanners and laser trackers, providing real-time inspection capability.