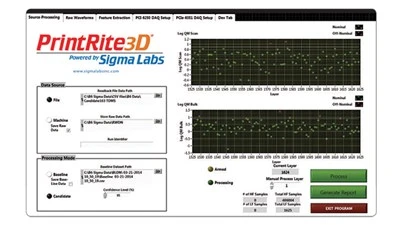

Sigma Lab's PrintRite3D INSPECT V.2.0 builds on the company’s integrated, interactive system that combines inspection, feedback, data collection, and critical analysis. The system pairs SENSORPAK multi-sensors and hardware with INSPECT, CONTOUR, and ANALYTICS software modules for comprehensive management of additive manufacturing (AM) processes. The V.2.0 release is both web and IoT-enabled and features statistical process control (SPC) and visualization, providing a real-time snapshot of the entire process, part-by-part multivariate analysis. It also allows for machine floor to cloud data communication with multiple machine system integration.

Morf3D, the company’s commercial alliance partner for 3D printing, as well as Honeywell Aerospace, will receive the first installations of the new PrintRite3D INSPECT V2.0. As a result of such installation, it is believed that Morf3D will be able to provide a means for customers to increase AM production rates while ensuring consistent part quality. Honeywell Aerospace will use PrintRite3D INSPECT V2.0 during Phase 3 of its rapid qualification for AM program sponsored by DARPA.