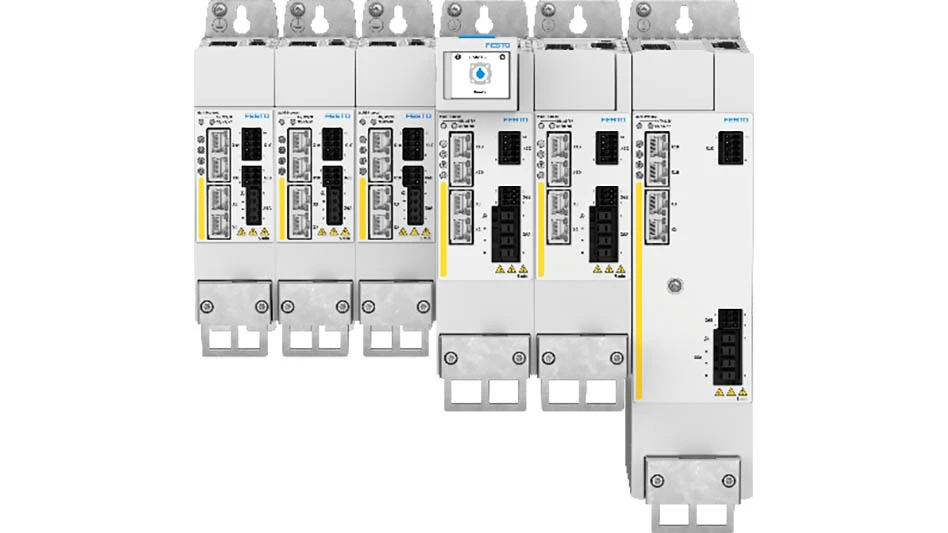

Photo credit: Festo

Festo’s CMMT-AS-S3 servo drive series enables machine builders to achieve higher levels of functional safety while simplifying design, wiring, and certification. The CMMT-AS servo drives give OEMs a choice between two distinct safety levels – Basic (S1) and the new Advanced (S3) – offering a flexible, cost-effective way to meet safety and performance requirements without added complexity. All CMMT-AS servo drives are multiprotocol and configurable to EtherNet/IP, PROFINET, EtherCAT, and Modbus TCP communication protocols.

Simplified safety integration

CMMT-AS servo drives integrate key safety functions directly within the drive, minimizing external components and setup time. OEMs can choose to implement safety via hard-wired digital I/O or over a PROFIsafe network for seamless integration with Siemens safety PLCs. This flexibility allows OEMs to balance simplicity, performance, and cost across a wide range of machine types.

Festo’s intuitive Safety Configurator in the Festo Automation Suite commissioning software streamlines setup. Users simply select the desired interface and enter a few parameters to activate advanced safety functions. A forthcoming Validation Wizard (expected winter 2025) will automate documentation by guiding engineers through verification steps and generating a safety report for certification records.

Two-tier safety offering

The Basic (S1) version, designed for straightforward, cost-sensitive machines, provides standard safety functions and fast commissioning through simple hard-wired connections.

Functions include:

- Safe Torque Off (STO) – cuts power to the motor to prevent motion

- Safe Brake Control (SBC) – engages the motor brake for vertical or gravity-loaded axes

- Safe Stop 1 (SS1) Type c – performs a controlled stop before removing power (requires an external safety timer)

- Diagnostic outputs for Safety Trip Alarm (STA) and Standby Alarm (SBA)

The Advanced (S3) model works for complex machines requiring greater safety functionality and configuration options. The S3 model adds a fully integrated suite of safety functions and eliminates many external components. These advanced safety functions can be used in combination with Festo motors EMMT-AS with integrated safety encoders.

Additional functions include:

- Built-in SS1 timer – no external timer required

- Safe Stop 2 (SS2) – controlled stop while maintaining servo control

- Safe Operating Stop (SOS) – monitors standstill without cutting power

- Safe Limited Speed (SLS) and Safe Maximum Speed (SMS) – ensure motion remains below defined speed thresholds, supporting safe-motion applications such as collaborative robotics or semi-automatic operations

- Safety Over Network (PROFIsafe over PROFINET) – enables full safety control through a single Ethernet cable from a safety PLC

Ease of use and documentation

Festo engineers designed the new CMMT-AS generation for simplicity. “It’s surprisingly easy to implement,” said Tom Worsnopp, Product Market Manager for Electric Automation at Festo. “With a few parameter settings in the configurator, the user can activate and validate advanced safety functions in minutes. And the upcoming Validation Wizard will automatically create the required documentation.”

To safeguard certified configurations, each safety setup is password-protected through a dedicated safety-engineer login, ensuring parameters remain locked and traceable after validation. This capability also supports Festo’s compliance with the upcoming European Cyber Resilience Act (CRA).

Part of a growing safety ecosystem

The CMMT-AS servo drive series expands Festo’s comprehensive safety ecosystem, which includes actuators, motion solutions, and control software designed to improve reliability and reduce risk. By embedding more safety functionality directly into the drive, Festo helps OEMs speed up machine certification, reduce wiring, and build safer, more productive systems.