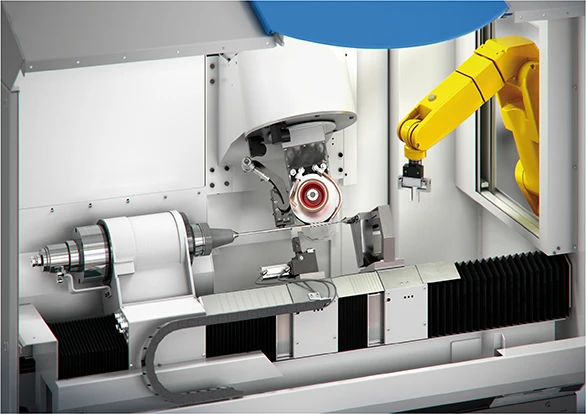

Jackson, Michigan - Schütte today announced the introduction of its new 325linear machine, a grinder CNC 5-axis motion with extended executive xy-ancillary and two slides for mounting holes of the workpiece and better orientation of the wheel on all mechanized wrapping. Micro tools, drills, cutters bucket and complex geometries can be accommodated in this new machine, which operates in the range of 2500-4000 rpm, typically. The addition of the auxiliary slide segunada allows the 325linear use the tool orientation, support part, counterpoint or pallets of work in operation. This new machine Schutte further increases the possibilities of automation user, as also offers significant advances in the change wheel and the workpiece handling robotic work.

Check out the 2016 IMTS Conference!

Specifically, a shaft-user can install chucks clamps, hydraulic or mandrels mandrels expansive various scopes. Changing the clamp allows automated without human intervention hold pieces with different diameters concentric completely. Axis configuration to Schutte on this machine also allows mounting holes oriented position without rotational symmetry pieces. Thus the pieces sequential work with several roughing and finishing requirements can be programmed into the machine for continuous processing.

this new milling system Schütte also provides scalable automation with a tool changer 140-position wheel magazine 5-24 and a flexible robotic gripper tool to change the smallest micro tools available as options. The same basic machine can sr used for continuous production of one piece in a cell configuration or used for sequential jobs as needed.

The 325linear has a rotation of the x-axis universal with a high level of concentricity (<0.0001º resolution) and accuracy, while the xyz-axis resolution is maintained at <0.1 microns. The c-axis swivel the grinding head has a range of motion of 225 °, also accurately resolution <0.0001.º the primary spindle up to 12,000 rpm engine operates with 15kW output motor max., While the spindle option ground offers speed max. 24,000 rpm. Linear axis travel in the machine is (xyz) 480mm x 250mm x 275mm.

The machine is offered with SIGSpro (Schütte Integrated Grinding Software) property as a programming interface, allowing users to assign options mounting holes for each milling operation being performed. When the support system and the tool guide, predefined distances of the wheel to the workpiece can be defined and maintained constant are used. In 3D mode all steps of the cycle can be simulated, controlled and optimized for accurate estimation, collision avoidance and even the integration of external workstation with the other workpieces.

Source: Schütte