Photo credit: Fairlane Products

Fairlane Products, a North American supplier of workholding technologies and machine tool components, provides a wide range of round-style replaceable gripper pads in inch and metric size diameters for an ever-growing list of demands on workholding and positioning components. Those demands include dealing with hard alloys and exotic metals, intricate shapes and contours of castings and forgings, higher spindle RPMs, and machines that multi-task.

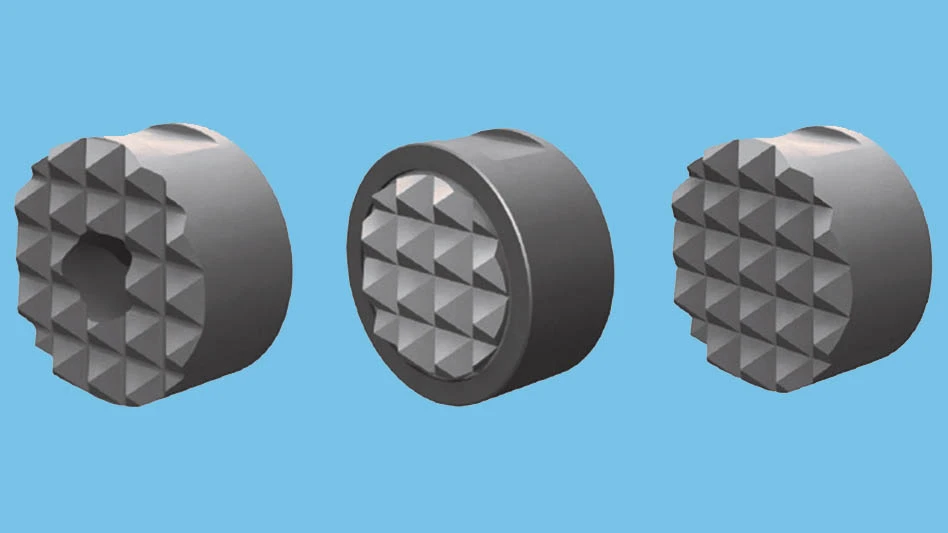

The round-style pads are available in three versions: high-speed tool steel, carbide tipped, and solid carbide. They are easily replaceable within workholding and positioning devices. The pads can have super fine, extra fine, fine, coarse, or single point pitches and either diamond or straight serration patterns along with sizes and mounting options for secure holding, positive contact, and long wear.

The high-speed tool steel pads are manufactured from M-2 tool steel, hardened to Rc 62 with black oxide finish. They are available pads from 1/4" to 1" and 12mm to 25mm diameter and from 1/8" to 5/32" thick.

The carbide tipped version is manufactured with high-impact carbide brazed to a heat-treated alloy steel body and is mounted with a tapped hole or a flat on the outside diameter for setscrew mounting. They are available in 3/8" to 1” and 10mm to 25mm diameters.

The solid carbide replaceable grippers are also made from high impact grade carbide with a threaded brazed-in steel insert. They provide toughness and long service life, helping to protect expensive fixture components from damage and wear. They also help maximize uptime while affording secure holding strength and positive contact to a variety of workpiece shapes, sizes, materials, and dimensional variations.

Solid carbide round style range from 1/4 "to 1" diameter and from 3/8" to 1/2" height. The thin pads are for workholding applications where limited access space or limited fixture travel makes loading, unloading, and secure holding difficult.