Credit: Caron Engineering

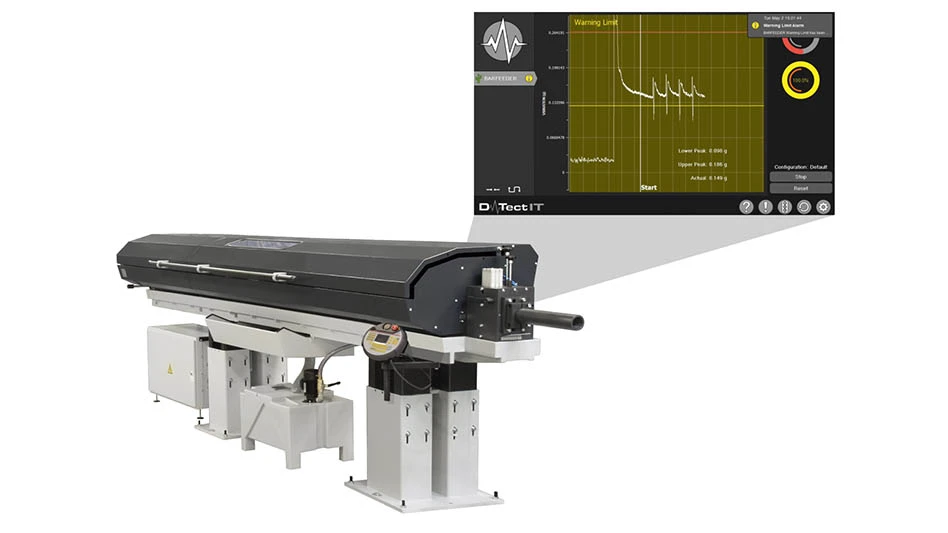

In the precision-driven world of CNC machining, material loading with bar feeder technology can be essential for process automation – but automation without real-time control can quickly lead to scrap, downtime, and equipment damage. Caron Engineering’s DTect-IT product features robust vibration detection and monitoring capabilities designed to identify and respond to excessive bar feeder vibration before it impacts part quality or machine health.

Bar feeders play a critical role in automated lathe operations, but imperfections in bar stock often go unnoticed until they cause costly issues. Material inconsistencies, alignment problems, and excessive vibration can result in:

- Dimensional inaccuracies

- Compromised surface finishes

- Increased machine wear and unplanned downtime

- High scrap rates

DTect-IT solves this challenge with a real-time monitoring and correction system that detects excessive vibration at the spindle and takes immediate corrective action – before part quality is affected.

Real-time vibration monitoring and automatic correction

DTect-IT uses a high-resolution vibration sensor mounted on the main spindle to continuously monitor vibration signals during cutting. When vibration exceeds user-defined thresholds:

- Automatic spindle RPM adjustments: The system signals the CNC to reduce spindle RPM incrementally until vibration falls within acceptable levels – keeping the process within tolerance and preserving part quality.

- Emergency stop capability: If excessive vibration cannot be corrected through RPM adjustments, DTect-IT commands the CNC to stop, preventing equipment damage and unnecessary scrap.

Key benefits and features

- Customizable vibration thresholds – Set user-defined vibration limits to trigger alerts or automated actions.

- Data logging & analysis – Record vibration trends for predictive maintenance and process improvement.

- Seamless integration – Compatible with a wide range of CNC lathes and bar feeder systems.

- Enhanced part quality – Detects and mitigates vibration before it impacts surface finish or dimensional accuracy.

- Reduced scrap rates – Prevents full-bar scrap by identifying problematic material early in the process.

- Extended machine life – Protects critical components by minimizing vibration-induced stress.

- Increased efficiency – Automated corrections reduce operator intervention and increase uptime.

- User-friendly interface – Simplified setup and intuitive monitoring tools require minimal training.

DTect-IT is not limited to bar feeder applications. As a powerful CNC sensor analysis platform, it supports a wide variety of sensor types – including vibration, strain, power, analog, and metrology inputs – giving manufacturers the ability to monitor, analyze, and react to a broad range of machining conditions in real time.

For more information about DTect-IT and Caron Engineering’s full line of manufacturing automation solutions, visit www.caroneng.com.