PHOTO CREDIT: FULCRUM

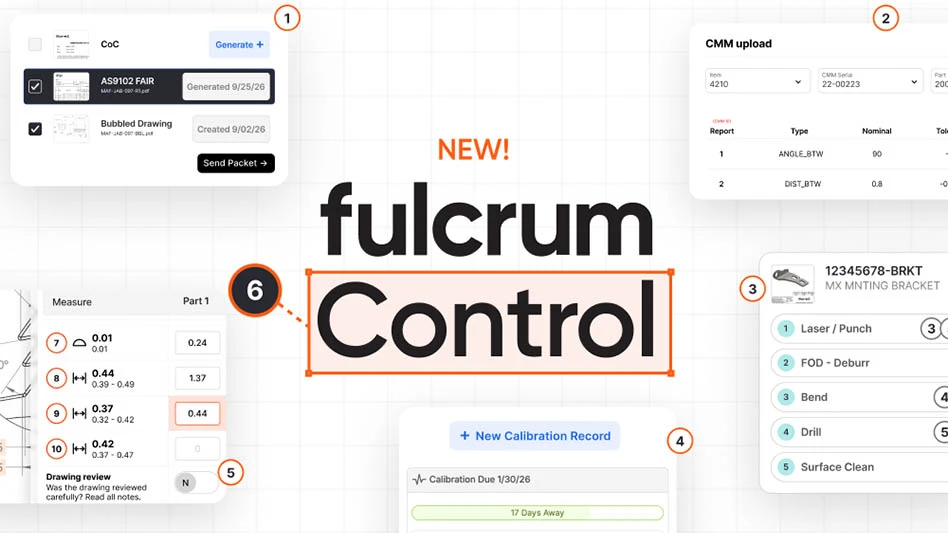

Fulcrum, a manufacturing technology platform that connects systems and people across the shop floor, has launched Control, a quality management product designed to meet the evolving needs of America’s manufacturing network. With rising U.S. investments in space exploration and defense, this product development arrives at a critical moment, empowering manufacturers to meet escalating demands on the domestic supply chain. Control makes quality workflows simpler and coordination tighter within shops and for their customers. Founder & CEO Sunny Han shared, “Existing tools solve part of the equation, but no modern system ties production and quality control together. We built Control alongside our aerospace and defense manufacturers to solve the coordination problem every quality shop has. When quality lives in a silo, teams act on incomplete information and throughput suffers. Today we're launching a product that solves that problem.” Notably, Control raises the bar for the coordination, efficiency, and execution of quality management to meet AS9100D and ISO 9001 and supports ITAR requirements. For manufacturers aiming to solve the tension between speed and compliance: Control is made for you.

How it works: Built on rapidly advancing AI models, Fulcrum’s new Control product gives shops precise command over how drawings are annotated and shared. Users can define how prints are auto-bubbled, execute quality plans, and send reports directly to customers all while reducing manual data entry. Tightly integrated with Fulcrum, Control strengthens the Autoschedule function by deepening its understanding of a shop’s real-world constraints, levers, and capacity. A simple, intentional interface clearly shows which bubbles require which measurements and when, reducing operator error while unlocking new efficiency gains that will continue to improve over time. Fulcrum’s vice president of Product, Alex Troesch, said “Our customers have played a central role in shaping this new product over the past several months. We’ve spent a lot of time listening to CNC and sheet metal fabrication shops, especially those in space, aerospace, and defense, where quality systems are non-negotiable. But what we learned applies well beyond those industries. Again and again, what we've found is that when quality processes are integrated with production and more precise, we can unlock real, valuable capacity without cutting corners. Control is built for high-precision, compliance-heavy environments, helping teams do their best work with confidence and deliver reliable, safety-critical outcomes.”

Demo Control and Join Upcoming Livestream

Control is available now to all Fulcrum customers. Learn more at fulcrumpro.com/control. For those new to Fulcrum, you can sign up for a demo by visiting fulcrumpro.com/demo. Fulcrum is also hosting a livestream to launch Control with lives demos on February 18, 2026 from 1pm to 2pm CT. Register for the livestream at fulcrumpro.com/launch-control to join and ask questions to Sunny Han, Founder & CEO, and Alex Troesch, VP of Product.

Fulcrum is a cloud-based manufacturing software platform designed to help manufacturers connect their shop floor with real-time data to make better, faster operational decisions. Comprehensive tools include digital job tracking, automated production scheduling, precise job costing, and integrated workflows spanning quoting, BOM & routing, inventory, purchasing, quality control, and live reporting. By replacing paper-based processes with connected, live information, Fulcrum enables manufacturers to optimize production efficiency, reduce waste, and improve profitability.