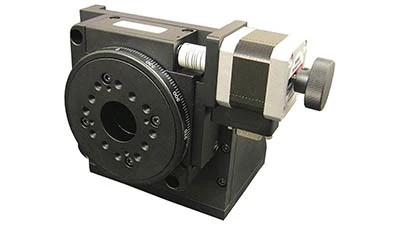

Van Nuys, California – Optimal Engineering Systems Inc. (OES) has released the AY110-100V Vertical Rotation Stage. The 100mm (3.397") diameter vertical rotation stage has a 30mm (1.181") diameter clear aperture to allow for: cabling, vacuum lines, clamping, and laser alignment. A precision pattern of threaded mounting is provided to add custom tooling. The AY110-100V Vertical Rotation Stage is for: metrology, positioning of mirrors and lasers, laser machining or scribing, micro robotics, scanning, electronic assembly, testing, photonics, and vision systems.

Rated for a side load up to 2kg (44 lb), this vertical rotation stage features a 180:1 precision worm drive and deep grove ball bearings for a resolution of ±0.001° when microstepping (10 micro steps-per-step). The stage also features 0.005° repeatability, 0.001° positional accuracy, 0.005° backlash, and can rotate continuously.

A knob on the motor shaft allows for manual positioning (a scale clearly displays the angle of rotation); however, the knob may be replaced with an optical encoder for position verification. The footprint of this black anodized vertical rotation stage measures 110mm x 100 mm (4.331" x 3.937") for stability and has four mounting holes for integration into new and existing applications. Compatible with OES motion controllers, the AY110-100V Vertical Rotation Stage is available as a complete plug-and-play system, with an optical encoder for position verification, or with servo motor and optical encoder.