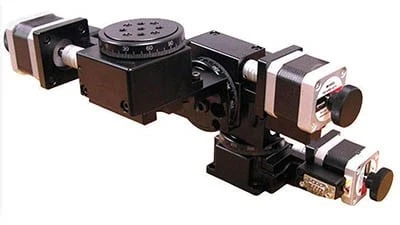

Van Nuys, California –Optimal Engineering Systems Inc. (OES) has introduced three new 3-axis miniature gimbal mounts with overall height less than 170mm (6.693"). These compact, motorized, high accuracy yaw, pitch, and roll stages are for prototype development, reverse engineering, use with a coordinate measuring machine, laser scanning, and in robotic or manual assembly when exposure to multiple surfaces is required.

The YPR60-60-60-01 (stepper motor driven - pictured), the YPR60-60-60-02 (brushless servo motor driven), and the YPR60-60-60-03 (DC servo motor driven) are stacked precision rotary stages with positional accuracies of 0.05°, repeatability of ±0.01°, and resolutions are dependent on the stepper motor driver (open loop operation) or servo motor and optical encoder (closed loop operation).

Each axis is driven by a 180:1 worm gear and has a large range of travel. The top axis (roll axis) has a 60mm (2.362") diameter table and a precise pattern of threaded holes for fixtures or tooling.

The maximum speed with stepper motors is 14°/second and 45°/second with servo motors. All axes have a Home signal for initialization Additionally, each axis has a calibrated indicator to display the rotation angle.

The knobs of stepper motors can be replaced with optional optical encoders for position verification. The YPR60-60-60-02 and YPR60-60-60-02 feature servo motors and optical quadrature encoders for precise closed-loop operation and greater speeds.

The YPR60-60-60 (01, 02, and 03) stages can be ordered plug-and-play with a compatible multi-axis motion controller from OES.