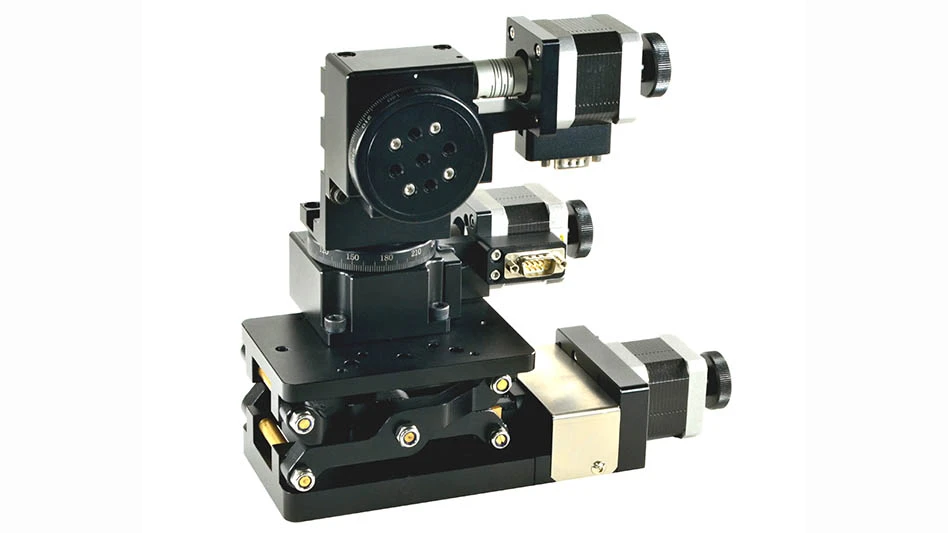

PHOTO CREDIT: OES

The LPT-60-60-60 series of lift, pan, and tilt motorized motion control stages have been released by Optimal Engineering Systems Inc. (OES). The compact stages feature a lift-axis with 60mm (2.362") of vertical travel, a horizontally mounted pan-axis (rotary) stage, and vertically mounted tilt-axis (rotary) stage. The scissor lift design combined with precision roller bearings and slide rails assures smooth motion and very high parallelism throughout the raising and lowering of the lift table.

The pan-axis stage is capable of up to 180° of CW or CCW rotation (cable routing limited) and the tilt-axis is capable of 360° of continuous CW or CCW rotation. The LPT-60-60-60-01 stage (shown) is driven by two-phase stepper motors with micro-stepping capabilities. The vertical repeatability is typically ±5 microns and typical positional accuracy is 15 microns. The LPT-60-60-60-04 is driven with two-phase stepper motors and has quadrature incremental optical encoders for position verification. The LPT-60-60-60-02 is driven by three-phase brushless servo motors with quadrature incremental optical encoders, and the LPT-60-60-60-03 is driven by DC brushed servo motors with quadrature incremental optical encoders. The servo motor options provide higher repeatability and positional accuracy, that are typical of a closed loop system and faster travel speeds.

The integration of high parallelism vertical lift and horizontal and vertically mounted high precision rotary stages is ideal for: Laser pointing, laser milling and drilling, camera mount, mirror alignment, range finding, sighting, assembly and inspection, scanning, and reverse engineering, in laboratory and manufacturing applications. These stages require a motion controller that can be ordered as a complete plug-and-play system with RS-232, USB, joystick, and keypad control.