Seco Tools Inc. has announced the availability of custom tooling to complement its standard Jetstream Tooling offering of high performance tools designed to deliver coolant directly at the insert cutting edge for productivity gains. The custom ordered tools come in a range of semi-standard modular cartridges and toolholders available for use in certain heavy duty applications. These include ISO CNMG 4, SNMG 4, DNMG 4, VBMT 3, CCMT 3 as well as Seco’s highly versatile MDT, multi directional turning system in 4, 6 and 8mm right handed cartridges in two reach lengths – 3xB1 and 5xB1.

The cartridges are designed to fit either the Jetstream Modular square shank or C6 Seco–Capto toolholders. Toolholders with a Versatec joint are also available as a custom order.

When used as a modular system, the toolholders can be adapted to suit most tool holding configurations. The toolholders and cartridges are made to order in Seco’s own custom tooling workshop.

Jetstream Tooling achieves appreciably better chip control along with increased tool life and cutting speed and feed rates across virtually all coolant pressures (70psi—5000psi) and many material types -- specifically titanium alloys, but also nickel-chromium, aluminum and steel alloys, as well as stainless steels. Numerous field tests have shown the use of JetStream Tooling in conjunction with a variety of water-based or cutting oil coolants applied at pressures between 200psi to 5,000psi can reduce cycle times by up to 50% and increase tool life by 75%.

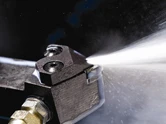

The beneficial effects of JetStream Tooling are due to a combination of mechanical and thermal properties of the jet. Coolant is applied through the tooling nozzle at high pressure close to the cutting edge, cooling the work area and producing smaller, hard, brittle chips. The high pressure jet then breaks and lifts the chips away from the cutting area without damaging expensive components or tooling. Additionally, there is less contact length of the chip on the rake face, which helps to prevent crater wear and improve surface finish.