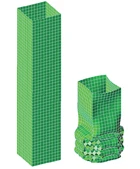

AMPS Technologies Company, a provider of Finite Element Design Analysis Software, announces the release of AMPSolid version 4.0 with the innovative Meta- Meshing method for high-quality meshing using a Meta-Element building block concept. The Meta-Element building blocks can be copied, rotated, joined, swept or extruded to create the desired shape just like the standard solid modeling parts in an assembly operation.

Meta-Elements have 1D, 2D or 3D formats and can be used to create beam/rod, surface or solid mesh elements all in the same model. Once the Meta-Elements are created, it is easy to change mesh density. This change is automatically propagated to other Meta-Elements for mesh consistency, and the final global mesh density can also be scaled up or down if desired.

Meta-Elements support the geometric selectors in AMPView (the AMPS pre/post-processing program). By associating the material and boundary conditions with the geometry instead of specific finite elements, the models can be re-meshed and re-analyzed without having to reapply material or boundary information.

Meta-Meshing generates high quality mixed quad/triangle, 2D/shell and hexahedron elements. A global mesh density factor (which can be fractional) on the Export Meta-Mesh dialog allows the model to be re-meshed with more (or fewer) elements. Mesh divisions are determined by the segment number for each edge and can easily be changed. Changes are propagated to adjacent Meta-Elements so that the mesh is consistent (same divisions along common edges).

Meta-Elements can have curved edges/surfaces, and they are converted into consistent finite elements while keeping the edge/surface curvature. A ratio option is available for each mesh edge to provide a non-uniform mesh along the edge. The segment size changes geometrically so the ratio of the largest to smallest is the specified ratio. These meshes are often used in CFD boundary layer modeling.

Meta-Elements can be selected, deleted, copied, pasted, translated and rotated in the same manner as solid modeling objects. This can speed up construction of meshes with repeated sections. Meta-Element colors in AMPSolid are used to group meshes together for the geometry selectors in AMPView for material property identification. The material interfaces are automatically created for FEA applications such as fluid-solid interaction.