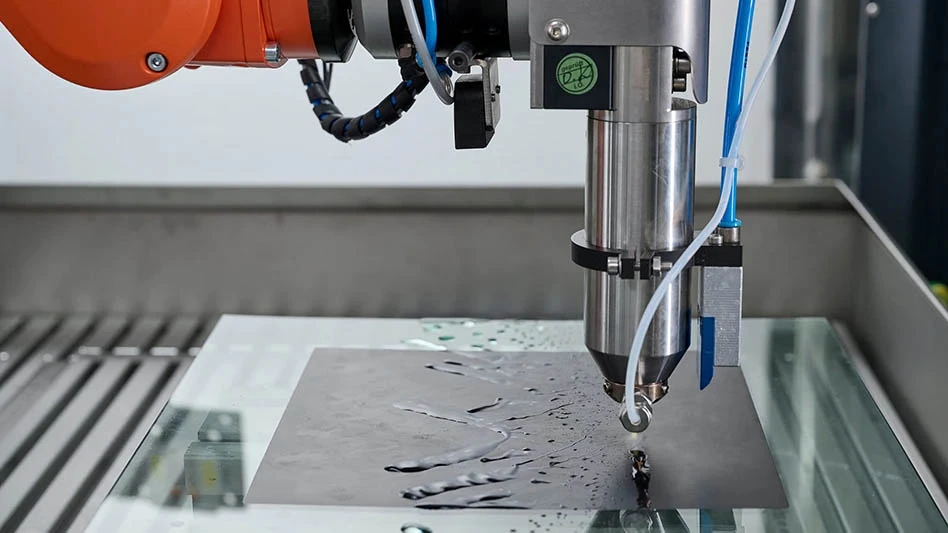

Photo credit: Plasmatreat GmbH

Plasmatreat GmbH, a global leader in atmospheric plasma technology, has unveiled HydroPlasma, an innovative, eco-friendly solution for ultra-precise cleaning of glass and metal surfaces. Combining the proven effectiveness of Openair-Plasma with the reactive power of ionized water, HydroPlasma removes stubborn organic and inorganic contaminants, including fingerprints, oils, salts, and grease, without chemicals.

Cleanliness in high-tech industries and processes

In automotive, electronics, aerospace, and medical manufacturing sectors, even microscopic contaminants can compromise adhesion in critical processes such as bonding, coating, printing, or sealing. Traditional cleaning methods often rely on solvents or wet-chemical treatments, but HydroPlasma delivers a chemical-free, sustainable alternative using only compressed air, electricity, and water. This advanced technology enhances cleaning efficiency and supports environmentally responsible production.

How HydroPlasma works: Science meets sustainability

HydroPlasma's patented process injects water into a plasma jet, where it ionizes into a highly reactive cleaning stream. A precision nozzle directs this stream onto surfaces, dissolving residues with a detergent-like effect – no harsh chemicals required.

Unlike conventional methods, HydroPlasma:

- Removes previously stubborn contaminants (e.g., fingerprints, inorganic residues)

- Preserves delicate substrates with a cooling effect that prevents thermal damage

- Boosts surface energy for improved wettability in downstream processes

Complementing Openair-Plasma

While Openair-Plasma remains ideal for light organic contaminants (dust, oils), HydroPlasma extends capabilities to challenging inorganic residues. Together, they offer a VOC-free, scalable cleaning suite for industries demanding zero-compromise cleanliness.

Applications across industries

HydroPlasma integrates seamlessly into existing production lines, including automotive manufacturing, electronics, and precision optics. Its gentle yet powerful cleaning is ideal for:

- Automotive: Ensuring flawless coating adhesion and structural bonding

- Medical Devices: Meeting sterile surface standards

- Aerospace: Preparing critical components for coatings

Sustainability at the core

By eliminating solvents and reducing waste, HydroPlasma helps manufacturers cut carbon footprints while maintaining workplace safety and process reliability.

What is Openair-Plasma?

Plasma is also known as the fourth state of matter, alongside solid, liquid and gas. When additional energy is added to a gas, it becomes ionized and enters the energetic plasma state. Whether plastic, metal, glass or paper, plasma technology is used to change the properties of the surface according to the requirements of the process.