GF Machining Solutions

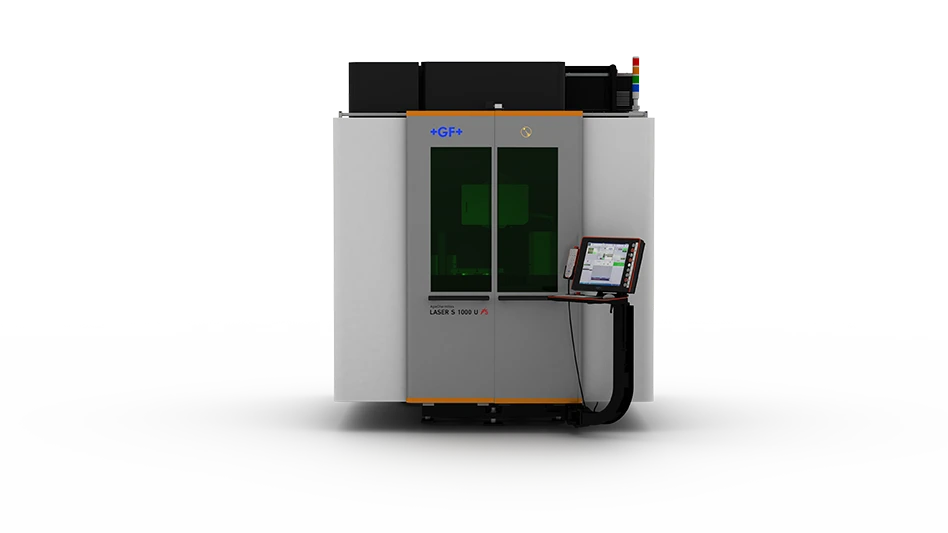

GF Machining Solutions presented its new LASER S 1000 U fs and LASER S 1200 U fs machines equipped with new ultrashort pulse laser sources.

Ultrashort pulse laser sources are well known for their excellent machining quality, achieving finest details and better surface roughness compared to nanosecond laser sources. The first machine equipped with an ultrashort pulse Laser was the AgieCharmilles LASER P 400 U, which introduced this powerful tool for texturing and engraving into the market.

GF Machining Solutions' AgieCharmilles LASER S 1000 U fs and AgieCharmilles LASER S 1200 U fs are now also equipped with a fiber femtosecond Laser. This will ensure a Laser machining process capable of creating finest details with enhanced quality while maintaining a high performance. It will also allow the processing of a wider range of materials that only femtosecond laser sources are able to machine efficiently, like ceramics, glass, sapphire, etc.

The launch of the two new machines is expected to increase the adoption of laser as a technical manufacturing solution in industries such as Automotive (for lighting, interior and exterior design), Packaging, and ICT. Nanolaser capabilities often could not satisfy requirements like the machining of complex, small geometries, a no-heat affected zone and the necessary surface roughness needed for applications in these industries.

Users will maintain the upmost flexibility thanks to the possibility to combine a nanosecond and a femtosecond Laser source in the same machine, switching seamlessly between the two sources in the same job. Depending on the application and the desired results, it is possible to use the strengths of each Laser source for the best combination of quality and productivity. The new femtosecond options work in perfect union with the latest software developments launched by GF Machining Solutions in 2022: Flexiblast and 3DCurves.

"We believe that the new femtolaser capabilities that we are integrating into our large Laser machines will not only meet the needs of our existing customers active in laser texturing and engraving, but also open up space for new applications in micromachining, attracting new customers in further segments like semiconductors or Aerospace", says Stefan Dahl, COO, GF Machining Solutions.

Ultrashort pulse laser sources are well known for their excellent machining quality, achieving finest details and better surface roughness compared to nanosecond laser sources. The first machine equipped with an ultrashort pulse Laser was the AgieCharmilles LASER P 400 U, which introduced this powerful tool for texturing and engraving into the market.

GF Machining Solutions' AgieCharmilles LASER S 1000 U fs and AgieCharmilles LASER S 1200 U fs are now also equipped with a fiber femtosecond Laser. This will ensure a Laser machining process capable of creating finest details with enhanced quality while maintaining a high performance. It will also allow the processing of a wider range of materials that only femtosecond laser sources are able to machine efficiently, like ceramics, glass, sapphire, etc.

The launch of the two new machines is expected to increase the adoption of laser as a technical manufacturing solution in industries such as Automotive (for lighting, interior and exterior design), Packaging, and ICT. Nanolaser capabilities often could not satisfy requirements like the machining of complex, small geometries, a no-heat affected zone and the necessary surface roughness needed for applications in these industries.

Users will maintain the upmost flexibility thanks to the possibility to combine a nanosecond and a femtosecond Laser source in the same machine, switching seamlessly between the two sources in the same job. Depending on the application and the desired results, it is possible to use the strengths of each Laser source for the best combination of quality and productivity. The new femtosecond options work in perfect union with the latest software developments launched by GF Machining Solutions in 2022: Flexiblast and 3DCurves.

"We believe that the new femtolaser capabilities that we are integrating into our large Laser machines will not only meet the needs of our existing customers active in laser texturing and engraving, but also open up space for new applications in micromachining, attracting new customers in further segments like semiconductors or Aerospace", says Stefan Dahl, COO, GF Machining Solutions.