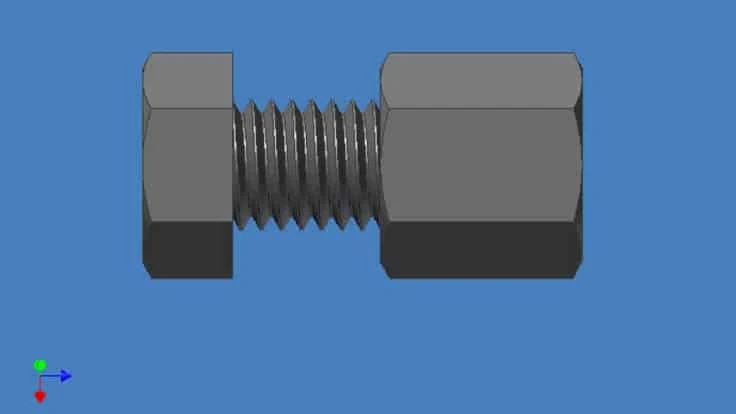

To prevent automotive critical fastener loosening when vehicles are subjected to vibration, shock, dynamic loading, or thermal stress, ForeverLok fastener design physically prevents bolt loosening without the traditional limitations of excess weight, complexity and length of typical locking fasteners or adhesives. The design involves three items: a central threaded fastener, a threaded intermediate fastener, and a retaining fastener.

The fastener system holds the nut in place to physically prevent it from loosening and is more compact than the traditional nut and bolt configuration of competitive products. The locking design does not use special pins, bolts, or tools to install or remove the nut, and only common tools are needed to fasten or unfasten.

The design allows the fastener to be smaller, lighter, and more compact than a larger fastener while providing a comparable torque value. The torque value of a ½-inch fastener tested greater than the recommended torque value of a 5/8-inch bolt.

The design is reusable many times, can be made of materials like titanium, steel, and alloys, and the flexible technology can be licensed so manufacturers can create their own products based on it.