PHOTO CREDIT: BLM GROUP USA

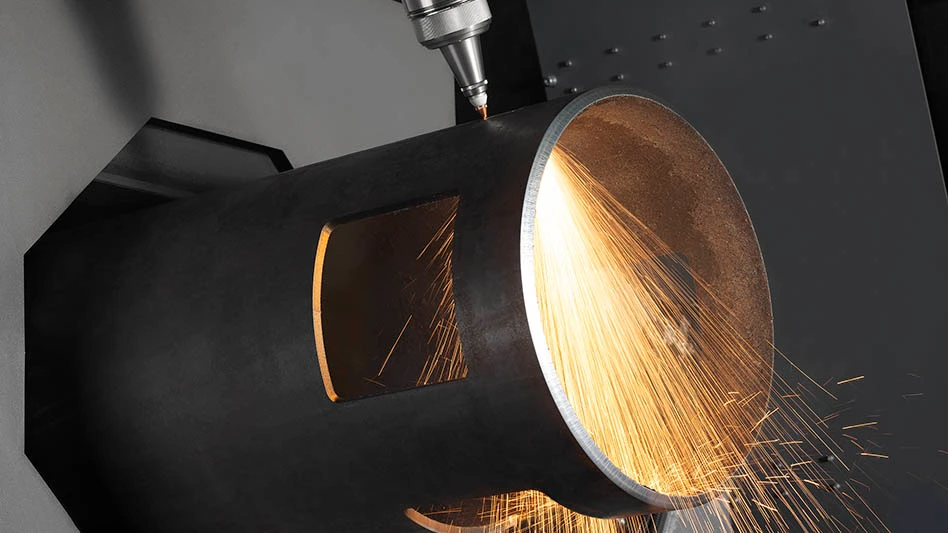

BLM GROUP USA introduces the LT14 Fiber Tube Laser, a next-generation solution for processing tube diameters up to 14" with greater speed, precision, and efficiency.

Building on BLM GROUP’s proven tube laser technologies, the LT14 Fiber delivers the benefits of advanced fiber laser technology – faster cutting on thin-walled tubes, improved cut quality on thicker and scaled sections, and lower overall operating costs. Its robust design makes it ideal for manufacturers in structural steel, energy, and power generation, off-highway and agricultural equipment, transportation, shipbuilding, and heavy equipment industries.

“The LT14 Fiber Tube Laser delivers outstanding benefits to help lower operating costs and increase productivity for the most demanding large tube fabrication applications,” said Lorenzo Carminato, business development manager at BLM GROUP. “Early pilot program feedback is excellent with one customer reporting a 50% increase in productivity over a previous LT14 CO₂ machine.”

Enhanced capabilities include automatic beam shaping technology for optimized cutting across diverse materials and thicknesses, advanced nesting software to maximize yield, and automated handling of tubes up to 54ft long. A unique short-part conveyor allows operators to automatically unload parts up to 10.5ft without requiring a scrap pit or micro-tabbing parts – eliminating secondary processing steps and enabling continuous, more efficient production.

The LT14 Fiber is equipped with three heavy-duty spindles that automatically adjust clamping force to match the material, ensuring secure handling during processing. BLM GROUP’s TubeCutter 3D head can position itself between any of the three spindles, a configuration that maximizes efficiency when cutting large-diameter tubes by keeping the tube stable and moving only the head. This design enhances rigidity, reduces wear, and eliminates the risk of scrap sections passing through the spindles.

Further, the spindles can seamlessly transfer the tube between one another, enabling full access to complex geometries and tail-end cuts. Finished parts are unloaded automatically – without the need for micro-joints – through an integrated part unloader that streamlines downstream operations.

The LT14 Fiber includes advancements in:

- Process flexibility – automatic beam shaping makes fiber laser cutting more efficient, versatile and precise across different material types and thicknesses, directly improving speed, quality and process stability.

- Productivity – combines a user-friendly HMI, Active Tools for automatic process optimization, and BLMelements software for comprehensive programming, simulation, and production monitoring.

- Energy efficiency – fiber lasers deliver more than 40 percent efficiency compared to only 10% to 20% achieved by plasmas. Fiber lasers also require less energy for cooling, which increases overall efficiency.

With the introduction of the LT14 Fiber, BLM GROUP continues to lead the way in innovative, high-performance solutions for large-diameter tube processing. Combining cutting-edge fiber laser technology and intelligent automation, the LT14 Fiber offers a powerful combination of speed, precision, and cost-efficiency for even the most demanding large scale industrial applications. As manufacturers seek to increase throughput and reduce operational costs, the LT14 Fiber sets a new benchmark in productivity, flexibility, and energy efficiency.