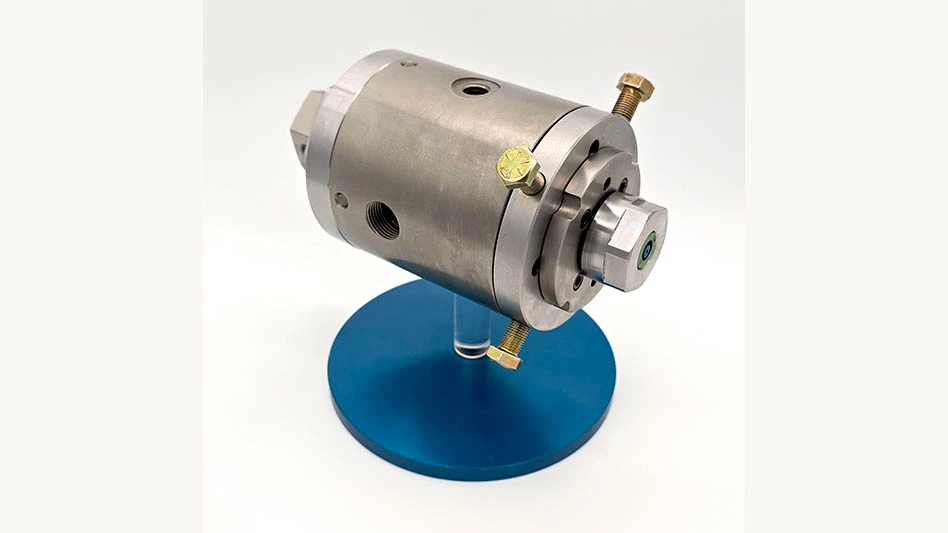

PHOTO CREDIT: GUILL TOOL & ENGINEERING CO. INC.

Guill Tool & Engineering Co. Inc., a provider of extrusion tooling, now offers the Unicam crosshead. The name derives from a combination of advancements made to two of the company’s most tried and true technologies: the Single-Point concentricity adjustment system and the Cam-Lock fastener-free assembly system.

On the front of the head, the new Universal Adjustment system allows the user to choose either the traditional 4-bolt method of concentricity adjustment or the Single-Point style of concentricity adjustment. To switch from traditional to Single-Point operation, simply remove the four locking bolts that hold the adjustment ring in place. If an application requires very fine adjustments, optional Micro-Adjust screws are available.

On the back of the head, the newly improved Cam-Lock system allows for the head to be disassembled with a single turn of a wrench for very quick and easy color changes or cleanouts. There is no need to struggle with hammers and pry-bars to disassemble components for cleaning. Thanks to the Cam-Lock system, turning the disassembly wrench not only loosens the splitter, but continuing to turn the wrench will mechanically extract the splitter. With just one half-turn of a wrench, users will typically be able to clean or change colors and start the line again in less than 10 minutes.