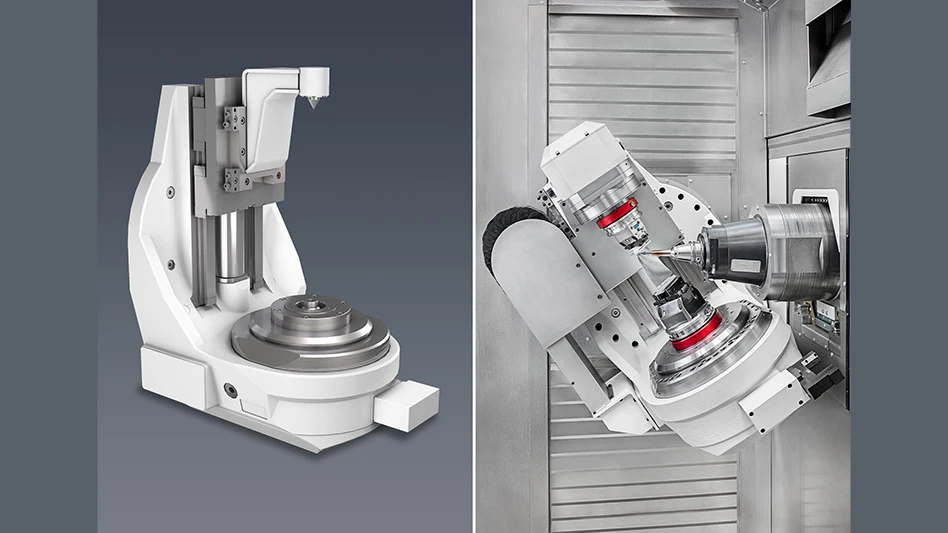

PHOTO CREDIT: GROB SYSTEMS

GROB Systems Inc., a developer of manufacturing systems and machine tools, has introduced its new VARIO Rotary Table providing a unique, adaptable solution for consistent, accurate machining of bladed turbine parts, and thin walled and slender parts. The VARIO Rotary Table features a customizable modular design ranging from a basic version to configurations with two highly dynamic, direct drive B-axes. The independently operating B-axes have specialized, innovative drive configurations to reduce stress during roughing, and to reliably prevent component distortion during finishing, producing superb surface finishes.

Available on the GROB 5-Axis G350 and G550 Universal Machining Centers which offer a highly stable horizontal design with a unique retractable spindle, integrating the VARIO Rotary Table ensures excellent surface quality on challenging parts of different materials and geometries, and large parts. Providing high flexibility, the new GROB VARIO Rotary Table has a movable counter-holder axis designed for a range of part sizes up to 27.6" (700mm) blank length.

“We are pleased to offer manufacturers with a new, reliable rotary table solution for optimizing precision and surface finish on bladed turbine parts and other demanding thin walled parts,” said Derek Schroeder, Universal Machines Sales & Proposals Manager, GROB Systems, Inc. “The new VARIO Rotary Table sets new standards for the manufacture of turbine blades of all kinds.”

Learn more about the GROB VARIO Rotary Table.

Watch a turbine blade machining video GROB – G550 with Vario Table Blade featuring the GROB VARIO Rotary Table.