Many of the world’s largest and most successful manufacturing organizations utilize Costimator OEM to identify part cost reduction opportunities throughout the product development lifecycle, leading to millions of dollars in cost savings.

Costimator OEM allows companies too quickly and easily identify the cost drivers in the products they design, manufacture and procure. This valuable information is then used to explore design alternatives and methods of manufacture that lead to lower cost products with higher profit margins.

Data Library

Costimator OEM comes with an unsurpassed library of real-world manufacturing data, including:

- 200+ Process Cost Models

- 2,500+ Work Centers

- 3,500+ Parametric Models

- 2,400+ Materials

- 3,400+ Labor & Machine Handling Standards

- Work Center Shop Rates for over 2 dozen countries

The key to any estimating tool is the reliability of the data it contains. Over 95% of the data residing in the Costimator OEM database library comes from MTI customers, which includes over 1,000 suppliers and OEM’s. The accumulation of this data over the past 25 years is validated during system implementation and then added to the Costimator OEM database library. This information is then shared with users on support through regular software updates.

Estimating Options

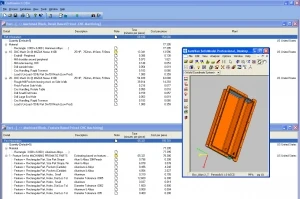

Costimator OEM provides two methods of creating cost models:

Bottoms-Up: An extensive data library contain the exact machine and labor times needed to produce cost estimates that are consistent with actual manufacturing times. This allows you to account for the time and cost of each operation. A complete, detailed cost breakdown analysis is developed, allowing you to identify what your products “should cost”.

Parametric: Parametric cost models are generated through regression analysis tables within IQBuilder, Costimator OEM’s parametric engine. Models can be developed for single or multiple level parts and assemblies.

Costimator OEM Organizational Benefits:

Design

- Determine the most cost effective designs

- Trade off cost factors with other product attributes

- Redesign parts at lower costs

Manufacturing

- Analyze current process methods, times and costs

- Calculate prototype and production costs

Procurement

- Utilize “Should Cost” models for negotiations with suppliers

- Find the best process-supplier match

Product Management

- Meet cost targets for new programs

- Reduce cost of programs in production

- Maintain an accurate current cost roll-up of all programs