PHOTO CREDIT: FIXTUREWORKS

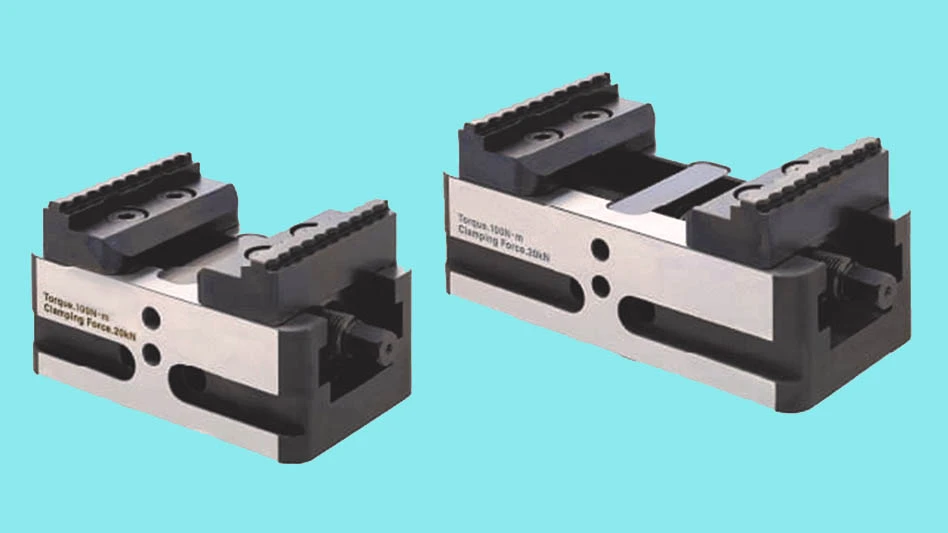

Fixtureworks, a supplier of workholding and fixturing technologies, now offers centering vises identified as CP170-N. Supporting the vise is a complete clamping system for workholding, including centering clamps, jaws, flex zero bases, and clamping pins.

Compact self-centering vises feature center-moving jaws for stability and are available in lengths of 130mm or 170mm, with widths of 80mm or 120mm. The high rigid design allows strong clamping force up to 4500 lb. The system is supplied with four locating screws for mounting. The vise (clamping) body is made from 4140 steel, induction hardened, precision ground, with a black oxide finish.

Dovetail jaws and serrated jaws for the CP170-N self-centering vises are available in 79mm lengths and 39mm widths. They hold the workpiece at two surfaces and provide positive clamping. Center-moving jaws provide stable workpiece centering settings. The small clamping area saves on the loss of material. Serrated jaws provide enhanced gripping for more aggressive operation and provide stable workpiece centering settings as well. Serrated contact surfaces penetrate the workpiece for powerful clamping. Both types of jaws provide for small clamping area. They are made from 4140 steel, quenched & tempered, with a black oxide finish.

Flex Zero bases locate and clamp workpieces, fixture plates, and vises primarily used for 5-axis machining with no tool interference. The bases, available in 240mm and 150mm square configurations with 4-point clamping in a single operation, shorten time during fixture change operations. Locating repeatability is 0.005mm. Used with CP185 clamping pins (sold separately) that are fully clamped to base in approximately three rotations of the single clamping key.

Four pins are available as a set for mounting the flex zero bases as well as a protective cover for unused holes in the base’s grid.