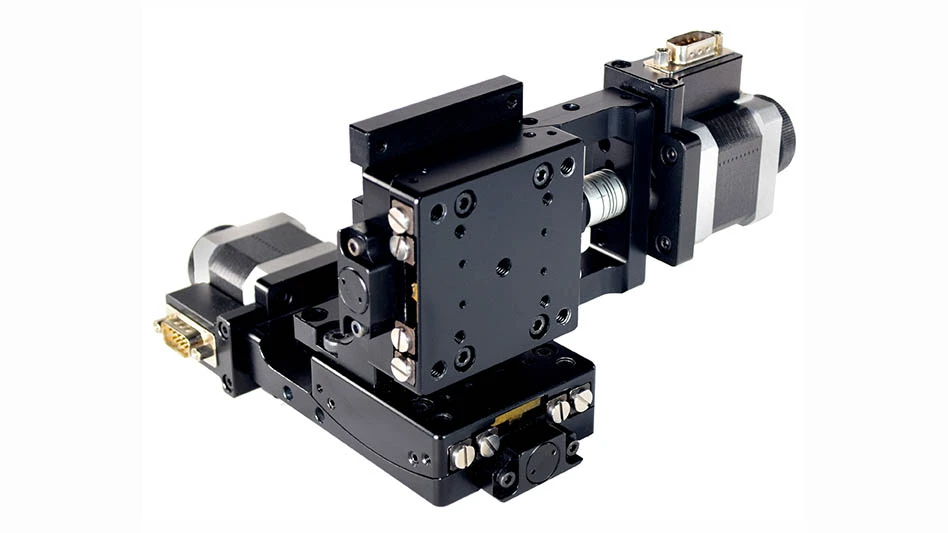

PHOTO CREDIT: Optimal Engineering Systems (OES)

A new series of Alpha-Beta “V” dual-axis goniometer stages have been released by Optimal Engineering Systems (OES). Mounted in an Alpha-Beta “V” configuration (one axis perpendicular to the other) a stage can position an object for inspection, align a mirror, and orient a camera or laser. The lower (horizontal-axis) goniometer stage features ±10° of rotation, the upper (vertical-axis) goniometer stage features a 65mm x 65mm table and ±15° of rotation.

The resolution for each stage of the AK110-10-15V dual-axis stage is 0.0007° (with a 10 steps-per-step micro-stepping driver), repeatability is ±0.01°, and accuracy is 0.05°. The series of AK110-10-15V Alpha-Beta “V” Dual-axis Stages have four motor options. The -01 option (pictured) is Stepper Motor Driven with knobs for manual adjustments. The -02 option is driven by Three-Phase Brushless DC Servo Motors with Quadrature Optical Encoders, and the -03 option is Brushed DC Servo Motor driven with Quadrature Optical Encoders. The -04 option is Stepper Motors Driven with Quadrature Optical Encoders for position verification. Greater precision and faster speeds can be achieved with the Servo Motor options in this series of stages.

Each axis of these motorized goniometer stages has End-of-Travel limit switches. These stages require a Motion Controller that can be ordered Plug-and-Play with Multi-axis Controller, Joystick, and Keypad.

Applications include: Measurement of angles, identifying crystals, moving an object to a precise angular position along an arc in relation to a fixed point in space, examine cutting edges of medical instruments, estimating hyperspectral bidirectional reflectance and gloss measurements, measure of radiation patterns of LEDs, directing lasers, align mirrors, and manufacturing of quartz oscillator plates using quartz cutting x-rays.

Other applications include: Animation, automated assembly systems, automation, CNC machines, flight simulation, inspection systems, linear and rotary stages, machine tools, medical devices, motion control camera boom systems, optical comparators, CMMs, pan-tilt gimbals, PCB assembly & inspection, pick-and-place, positioning stages, robotics, scanners, security cameras, telescope drive mechanisms, time-lapse photography and winders.