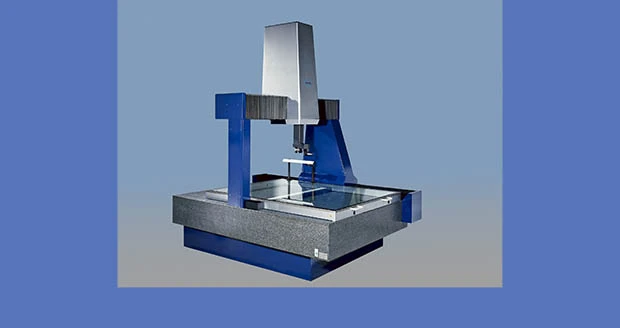

Giessen, Germany – The ScopeCheck MB from Werth Messtechnik GmbH is a multi-sensor coordinate measuring machine with air bearings for measuring large workpieces in a production environment. To produce precise measurement results even in a non air-conditioned space, this series of machines is equipped with a temperature compensation system.

The measurement range of the machines can be up to 1,500mm in the X-axis, 5,000 mm in the Y-axis, and 1,200mm in the Z-axis.

The integration of multi-sensors greatly increases the machine's flexibility. The patented Werth Zoom is fully integrated in the Z-ram of the measuring machine, providing unrestricted optical measurement capabilities. In addition to the optics and tactile sensors, the IP 40T rotating and tilting optical head can also be added along with a wide variety of additional sensor types. This makes it possible to optically measure large components from different directions completely automatically.

Using a special exchange mechanism, the IP 40T can also be equipped with the patented WFP Werth Fiber Probe. The Werth LLP laser line probe is available for rapid scanning and digitizing large components. All sensors are easily interchangeable using a park station in CNC mode. The optional back light attachment allows stamped parts, films, and other profiles to be measured throughout the entire measurement range of the machine.

The modular design allows the measuring machine to be expanded to meet future requirements.

Source: Werth Messtechnik GmbH

Latest from Aerospace Manufacturing and Design

- Air Canada discloses order for eight Airbus A350-1000s

- Post-processing solution for additive manufacturing

- Lee Spring India achieves AS9100D certification

- Coin cell supercapacitors

- How do defense industry trends affect your business?

- Stay ahead of the workholding technology curve

- CDT, DR. KAISER partner in grinding and dressing

- CT system for shop floor use