Paris – The International Paris Air Show, staging its 51st edition this year, has always been the epicenter for worldwide market development within the aeronautic and aerospace industries and has become, over the years, the privileged venue for these sectors of activity. For Vero, it's the perfect occasion to present its new CAD/CAM Viewer Analyzer and Trade Oriented ERP software solutions.

Visit the Vero Software stand in the Rhone-Alpes Pavilion, Hall 4, Alley E, Stand 133.

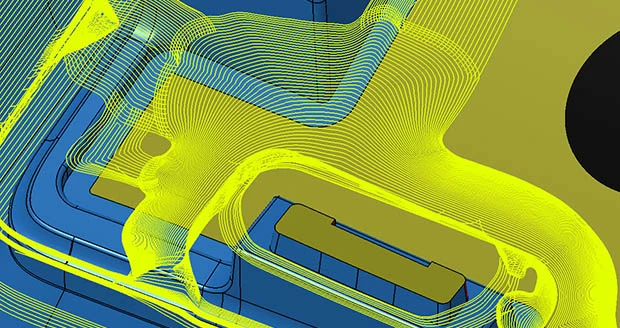

Featuring a range of 2D, 3- and 5-axis modules, WorkNC is well adapted for manufacturing structural parts made from diverse materials such as titanium, composites, aluminum, stainless and high-alloy steels, engine components, or tooling equipment. Lead-ins, lead-outs, stepovers, trochoidal movements; everything has been designed to optimize cutting conditions. Based on dynamic stock model management and comprehensive collision control – tool, tool holder, stock, machine kinematics – specialized toolpaths allow important stock removal rates under safe conditions.

WorkNC disposes of a wide range of functions and toolpaths for the finishing phase: vibration-free high speed machining leaving no marks, specialized 5-axis finishing, feature recognition, and automatic or interactive hole machining routines.

For the finishing phase for carbon or composite material parts, WorkNC proposes 5-axis machining cycles for both 'trimming' and 'drilling' operations which are capable of working from a set of points along with relevant coordinates and axis orientation data.

The feature recognition module allows different types of holes to be identified in the CAD model and to which can be applied personalized and predefined drilling, threading, and boring strategies.

VISI CAD/CAM covers design requirements with its hybrid, surface, solid, and wireframe modeler. Toolmakers appreciate the improved productivity offered by automated unfolding and the definition of intermediate stages for progressive tools or follow-on tools.

The Edgecam CAM solutions, geared to the serial production market, combine the power of generating complex toolpaths with the integration of uniform functions. They allow programming machining strategies such as turning, milling, and combined turning/milling in one single environment (turbine shafts, fan disks...).

The Waveform roughing strategy for turning in Edgecam 2015 offers material removal rates 3x higher than with traditional machining. The toolpath maintains a constant load on the cutter allowing higher feed rates and prolonged tool service life and takes into account the stock model to eliminate air cutting and reduce machining times.

Edgecam offers safe programming of multitask 3-, 4- and 5-axis lathes with turning and milling functions in the same environment. All cycles and movements are taken into account along with full modelization of the machine. The simulator also includes a tool to compare the machined model with the CAD model.

Source: Vero Software

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools