Whippany Actuations Systems makes electro-mechanical actuation systems for the aerospace and defense industries. The company needed to increase production quickly, preferred to manufacture in-house, and looked for an alternative solution to sinking a large expenditure into a new CNC machine.

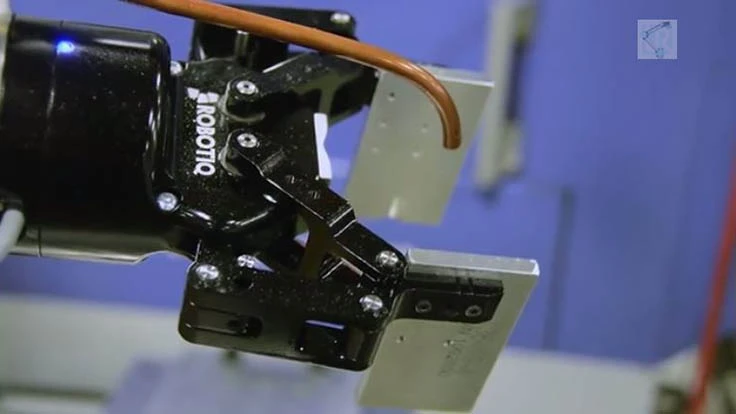

The manufacturer started researching a robot that could tend a CNC machine, and that’s when Whippany’s manager of manufacturing engineering, Phil De Mauro, turned to Universal Robots.

“We were looking for a solution that could be implemented and programmed easily and didn’t require the traditional guarding and safety that other robots required," DeMauro says.

The video below explains the process, and more details of this case study are here.

Latest from Aerospace Manufacturing and Design

- The Lee Company opens Innovation Center

- Precision XY gantry system

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family