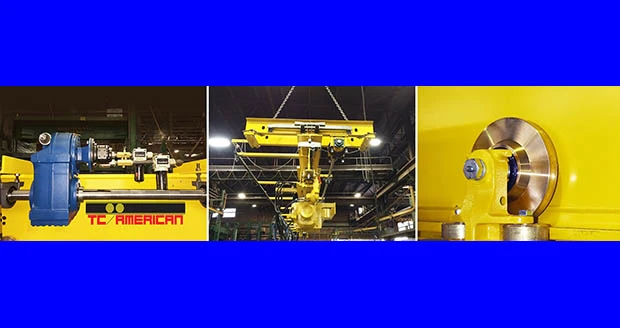

St. Michael, Minnesota – TC American Monorail has installed a custom-configured XP INTERLOCK spark resistant transfer crane in a paint booth area with flammable solvent fumes. This crane uses multiple patented track sections that are interconnected by special locking transfers at key transfer points, along with spark-resistant components for safe, explosion-proof operation in a hazardous area.

This custom configuration required a five-ton bridge crane that has the capability of using multiple track systems to allow unimpeded access to different parts of the plant without setting the load down. Keeping the load continually moving adds a measure of protection for delicate, high-value components that can be easily damaged. This allows the smooth transfer of the load from the assembly area to another part of the facility for final cleaning and painting using a separate track system. The continuous movement streamlines workflow patterns and enhances worker safety. The multi-track transfer is accomplished through the use of a specially designed mechanical interlocking mechanism that locks two separate track sections together in a direct, positive manner that ensures proper track alignment at all times. The interlocking feature also eliminates track flexing as a result of occasional off-balance loads.

In this installation the load was designed to travel to a paint area in which flammable solvent fumes are present, calling for spark-resistant equipment to keep the area explosion-proof. To eliminate the sparking risk all crane components that could act as a potential spark source were redesigned or replaced. The standard electric hoist motor was replaced with a 2.8hp air motor, fitted with a spark-resistant stainless steel festoon system to carry the air lines. Spring-loaded rubber tire drives are used on the end trucks, along with bronze idler wheels and side rollers. All metal-to-metal contacts that could act as potential spark sources are protected by stainless steel or bronze buffers to insulate the contact areas. The trolley drive system utilizes a 3/4hp air motor, with stainless steel safety drop lugs, to achieve a travel speed of 50fpm.

Through the combination of the direct interlocking track switching feature and spark-resistant construction, the crane offers safe and efficient transfers of delicate, high-value loads into hazardous areas.

Source: TC American

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators