Courtesy of Tech Sgt. Brad Fallin/USAF

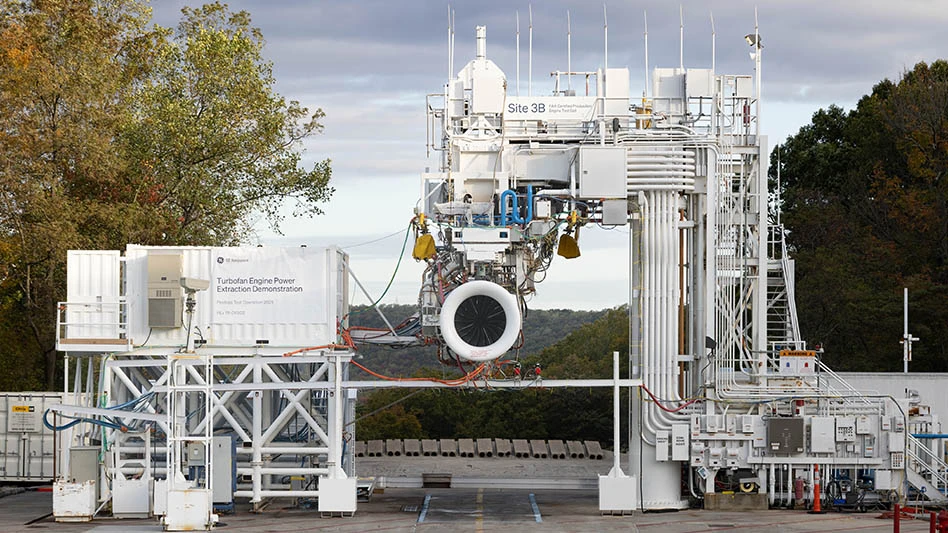

Southwest Research Institute (SwRI) has been selected for a five-year, $4.5 million contract from the U.S. Air Force Academy’s Center for Aircraft Structural Life Extension (CAStLE) to install Loads/Environment Spectra Survey (L/ESS) systems onto C-5 aircraft to monitor usage.

C-5 aircraft, first introduced in 1969, are large military cargo carriers designed to transport sizeable freight, including other aircraft. With a 222ft wingspan and 247ft length, they are among the largest aircraft in the world.

“The L/ESS system will capture usage data for the C-5 fleet,” said SwRI Senior Research Engineer Richard Lammons. “The system will support fleet management, monitoring the aircraft usage and updating inspection intervals as needed, to increase aircraft availability and reduce maintenance costs in the long term.”

The U.S. Air Force is required to monitor usage on 20% of the C-5 fleet to continuously assess its impact on the structural health, establish usage projections, and perform analysis and testing to evaluate and mitigate the impact of any fleet usage changes. SwRI will install the L/ESS systems on five C-5 aircraft during their scheduled maintenance at Robins Air Force Base near Warner Robins, Georgia.

“The data captured manually by crewmen include basic things like airspeed, altitude, fuel quantity and flight duration,” Lammons said. “These new systems will capture precise usage data, to determine if the C-5 aircraft are flying as expected and, if not, whether additional maintenance is required.”

SwRI will begin installing the L/ESS systems in 2024. Once installation is complete, the Institute will also perform component, subsystem, and system-level testing to ensure functionality.

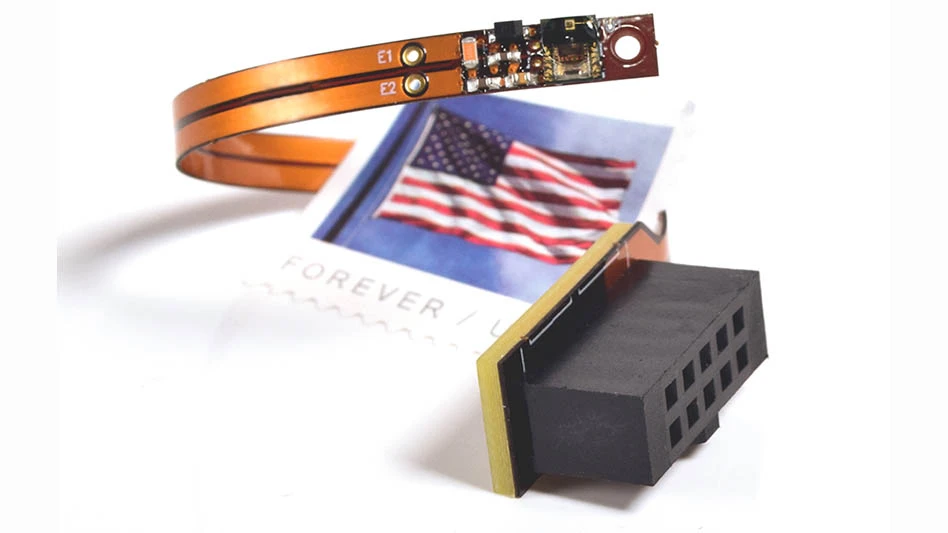

SwRI’s structural integrity work for the U.S. Air Force began in the early 1970s. Since then, the Institute has developed tools such as NASGRO® software, a collaboration with NASA that can analyze fracture and fatigue crack growth in structures and mechanical components. SwRI-developed flight data recording systems help engineers understand the structural stresses associated with various flight maneuvers and are currently flying on T-38 and A-10 aircraft. SwRI also developed specialized inspection probes, including technology to inspect through bushings without removal, and the SwRI-patented magnetostrictive sensors (MsS) flying on A-10 aircraft provide ongoing structural health monitoring.

Latest from Aerospace Manufacturing and Design

- Forecast 2026 Webinar

- America Makes announces two project calls worth $8 million

- Jaw force gauges

- Air India orders 30 Boeing 737 MAX jets

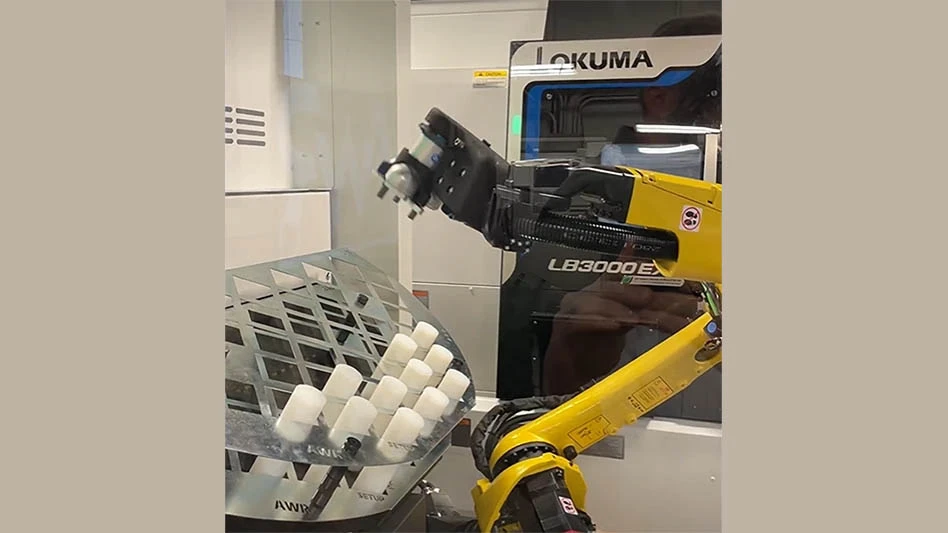

- Speed increasers for lathes, Swiss-style machines

- #81 Manufacturing Matters - Additive Manufacturing Analysis, Trends, Forecasts with Terry Wohlers

- A look at the latest in the defense industry

- Workholding Roundtable to feature expert insights on a booming market