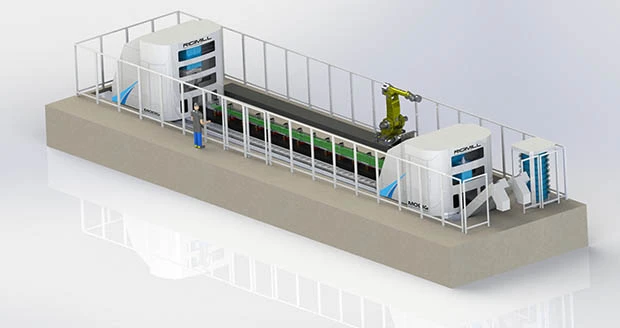

Chicago – Soosung Airframe has selected Modig’s RigiMill for its manufacturing needs, notably for wing stringers.

“Finally, there is a machine optimized for stringers. We will use this machine for the wingtop panels on the Airbus A320,” said Soosung’s Managing Director Mr. Joon Woo Cho. “With 40% faster production per part, Modig’s high speed solution is just what we need.”

Soosung Airframe, headquartered in South Korea since 1985, supplies aero structures for commercial, military, and business jets to the world’s leading aerospace companies.

Modig President David Modig said, “The 150kW spindle RigiMill will be customized for Soosung’s needs. For aluminum, we fit high a high-speed spindle together with a machine structure that is designed for speed and rigidity. The automatic pallet changer handles material in excess of 52ft.”

David Waldron, president of Modig’s U.S. operations, commented “The RigiMill is an exciting and disruptive technology that generates a tremendous return on investment for our customers, especially when coupled with an integrated pallet system for loading raw materials and unloading finished product. We are happy to run time studies for our customers to demonstrate the strong value-add delivered by the RigiMill.”

Founded in 1948, Modig has enhanced its reputation through its HHV extrusion mill and 6-axis FlexiMill prior to the RigiMill.

Source: Modig

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools