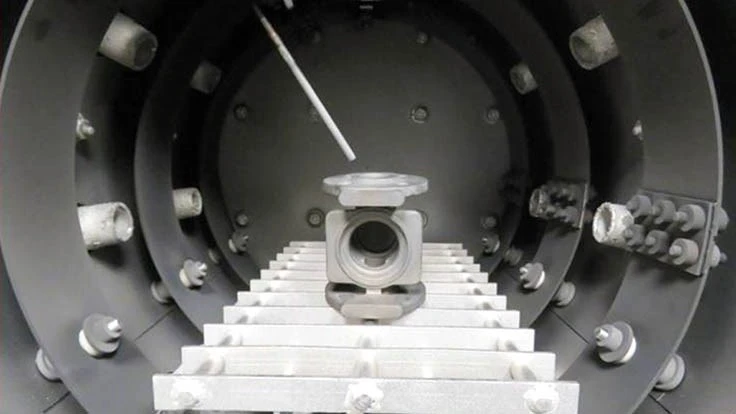

Hermitage, Pennsylvania – With the escalation of additive manufactured components being printed, and the increased production of engine blade manufacturing to support newer, more efficient aircraft, hot isostatic pressing (HIPing) is in greater demand for densification of many materials.

Throughout the years, Solar Atmospheres and Pressure Technology Inc. (PTI) have mutually understood their two companies’ complementary synergies. As an added value service, parts that require heat treat processing after HIP will be picked up by Solar from the PTI Concord, Ohio, facility at no charge.

Michael Johnson, sales manager for Solar’s Hermitage, Pennsylvania, facility, states, “As both vacuum heat treating and HIPing are gaining popularity, by providing the customer with both state-of-the-art services as one, we can offer quicker turnaround time and savings on shipping costs.”

Source: Solar Atmospheres

Latest from Aerospace Manufacturing and Design

- The Lee Company opens Innovation Center

- Precision XY gantry system

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family