Hamburg, Germany – Sekisui Polymer Innovations LLC, manufacturer of the Kydex and Allen brands of thermoplastic sheet products, has unveiled its Infused Imaging process.

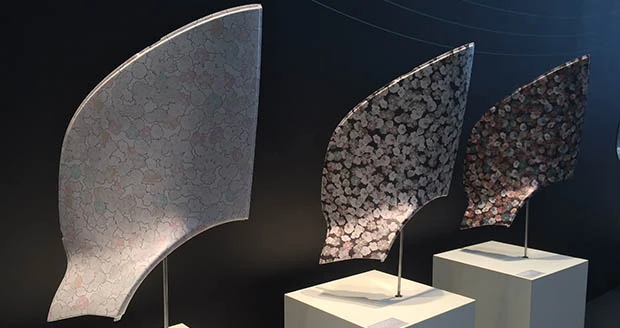

Thermoplastic surfaces with customized patterns and design are typically achieved by application of a cap layer to a polymer sheet, either during production or after thermoforming. For the first time in the thermoplastics industry, pattern-in-product is now possible. The process integrates design into the polymer through new technology that can be applied across the company’s product lines and industries the company serves.

Ronn Cort, COO & president of Sekisui SPI explains what this means for the aviation interiors industry and the company: “The industry is increasingly dedicating more resources to attracting and retaining customers through enhanced brand experience. In recent years, we’ve been listening to the challenges our customers have encountered when faced with sourcing materials for finish and effect that are compliant to aviation interior regulations. Decades-old technology like press lamination, application of decorative film caps, and bonded buildups all create challenges for the seating and interiors manufacturers. Now, customized, integral patterns and artwork created by the client can be used throughout the cabin as part of a design concept, which becomes part of the company’s brand, far beyond a name or color.”

Source: Sekisui SPI

Latest from Aerospace Manufacturing and Design

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification

- One-touch precision flex locators