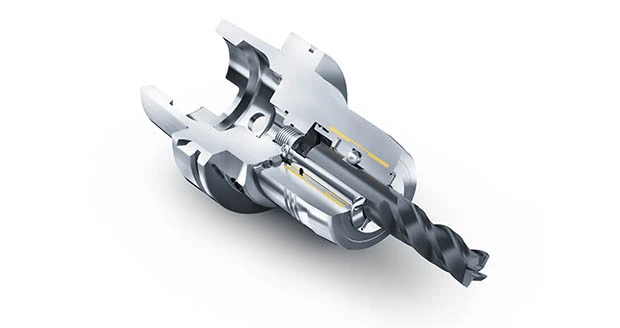

Morrisville, North Carolina – TENDO AVIATION combines the strength of hydraulic expansion technology with that of Weldon toolholders. This includes high run-out accuracy, a balancing grade of G 2.5 at 25,000rpm, vibration damping, and a fast tool change using an Allen key. An integrated anti pull-out mechanism provides tool orientation and form-fit clamping when using the Weldon shank. The mechanism prevents tool pull out, and positional tolerances can be held.

TENDO AVIATION allows maximum torque transmission at a consistently high precision and process reliability. With conventional Weldon and Heat Shrink toolholders, the run-out accuracy decreases over time. But he run-out accuracy and vibration damping of the TENDO hydraulic toolholders prevents the cutting edge from wear, extends the tool life, and ensures smooth surfaces. The uniform load profile also promotes a longer service life of spindle and spindle bearing.

This toolholder is available for the interfaces HSK-A63, HSKA 100, CAT 40, and CAT 50.

Source: SCHUNK

Latest from Aerospace Manufacturing and Design

- Precision XY gantry system

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification