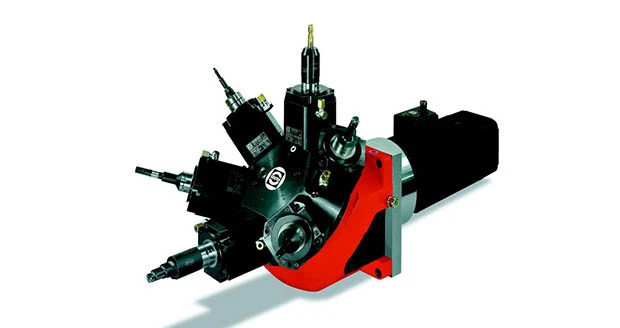

Ramsey, New Jersey – The Sauter family of crown-type live tool turrets, typically used on multi-station and in-line transfer machines, has recently been upgraded and expanded, with the largest having a standard drive motor rating of up to 20hp.

This series of ultra-high-speed and agile tool turrets uses a single motor for both turret indexing and live tool drive. Available with 4, 6, or 8 tool positions that are complemented with a wide variety of standard off-the-shelf tool spindles that use HSK quick-change toolholding adaptors. Multi-tool and special tool spindles are also available to meet specific application requirements.

These tool turrets can be used in any orientation and are lubricated for life. Alternatively, they can be connected to a central lubrication system, extending MTBF and reducing maintenance. With a rugged design and standard features such as tool speeds up to 15,000rpm, bi-directional high-speed indexing, a non-lifting tool carrier, high-speed/high-torque tool spindles, and an integral high-pressure coolant distribution system, these tool turrets are a choice for medium- and high-volume production machines for all industries.

Optional compact synchronous drive motors (compatible with most controls) that minimize acceleration and deceleration rates and reduce chip-to-chip times are also available.

Source: Indexing Technologies Inc.

Latest from Aerospace Manufacturing and Design

- Precision XY gantry system

- Archer to test Starlink onboard its Midnight air taxis

- System eliminates cage-creep in sliding bearings

- Bodo Möller Chemie signs worldwide supply contract with Airbus

- Sandvik Coromant's CoroTurn Plus turning adapter

- ZOLLER Technology Days & Smart Manufacturing Summit May 13-14, 2026 in Ann Arbor, Michigan

- Walter's TC620 Supreme multi-row thread mill family

- ThermOmegaTech achieves CMMC Level 2 C3PAO certification