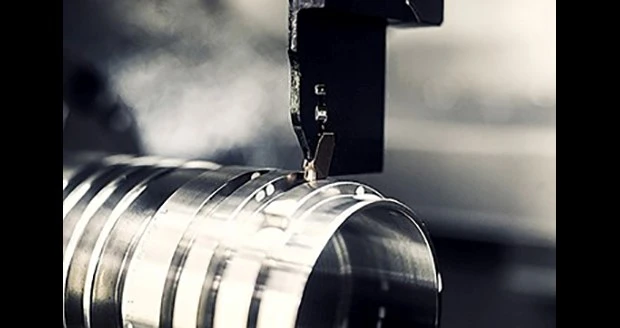

Fair Lawn, New Jersey – Sandvik Coromant officials offer a new white paper on “Parting & Grooving: How to achieve greater performance, quality, and tool life in the 21st century.”

Production engineers faced with overcoming the challenges of parting and grooving need reliable tools capable of delivering world-class performance in terms of productivity, quality, and tool life. To ensure that market demand is met, Sandvik Coromant has invested many decades and considerable resources in continuous research, development, and testing of parting and grooving technologies. Conducted in close cooperation with customers, each technology is developed to bring direct benefits to the end user. This white paper will share some of the knowledge gained throughout the years and serves as a guide to the latest cutting-edge technology and best practices for parting and grooving.

Source: Sandvik Coromant

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools