Rolls-Royce marked the official opening of its new £100m advanced aerospace disc manufacturing facility with a ceremony on June 5, 2014, conducted by Deputy Prime Minister Nick Clegg and Business Secretary Vince Cable.

When fully operational in 2016, the 18,000m2 facility in Washington, Tyne, and Wear in the northeast of England will have the capacity to manufacture 2,500 fan and turbine discs a year. These discs will feature in a wide-range of Trent aero engines including the Rolls-Royce Trent XWB.

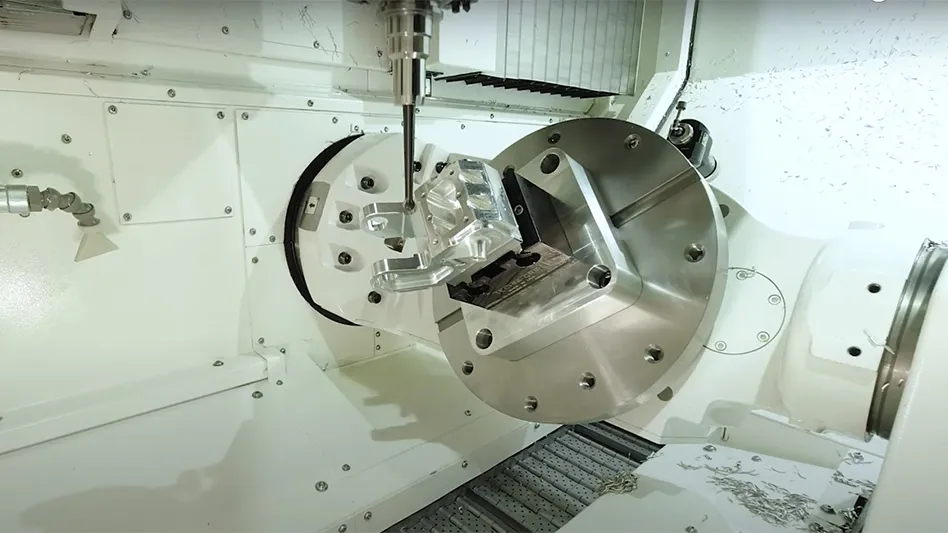

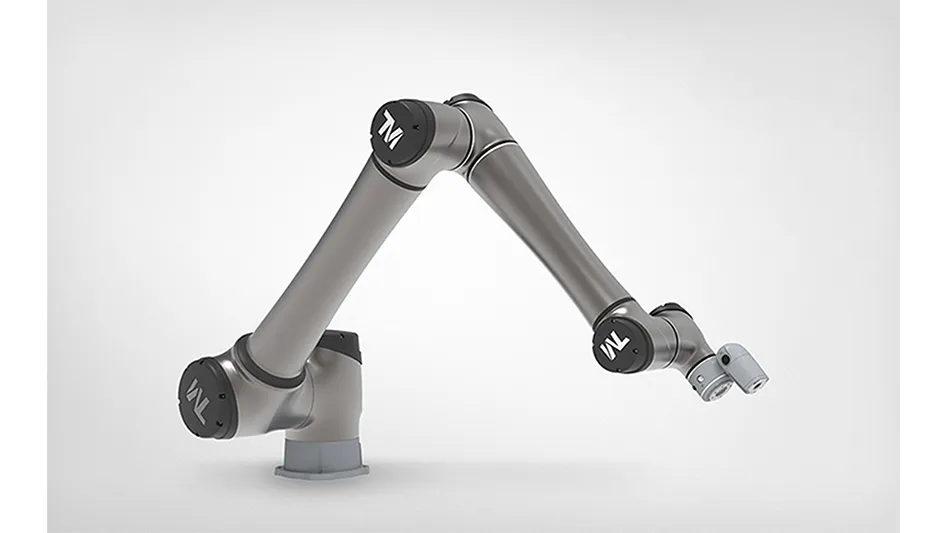

Ground-breaking manufacturing techniques include the introduction of robotics and automation for shot peen, painting, and chemical processing operations as well as latest advanced platforms for machining, grinding, broaching, and inspection processes. This has reduced the time it takes to manufacture a disc by 50% while producing a step-change in component performance. The state of the art facility makes use of manufacturing methods developed at the Advanced Manufacturing Research Centre (AMRC) in Rotherham. The AMRC is part of a network of research centers which aim to work with businesses to apply university research to accelerate the commercialization of new and emerging manufacturing technologies.

Tony Wood, Rolls-Royce, president of the aerospace division, said: "Rolls-Royce is committed to investing for future growth in order to deliver for our customers. We invested £687m in facilities and equipment around the world last year."

There are two types of disc manufactured at the Washington plant: fan discs and turbine discs. Located at the front of the engine, the fan disc holds the fan blades. There are typically 20 blades in each engine. They rotate about 2,700rpm and move 1.25 tonnes of air per second, the equivalent of the volume of air in a squash court. The fan discs remain in service for over 20 years.

The turbine discs hold blades in the hottest part of the engine where the operating conditions are at their most severe. The disc is made of some of the strongest materials available, created using refined powders which are specially processed and machined to the accuracy of a fraction of the thickness of a human hair. The blades that these discs hold each generate the power of a Formula 1 racing car and there are 68 of them in the Trent XWB. The temperature within the high pressure turbine is 1,700°C, hotter than the melting point of the turbine blades themselves, so they have to be coated with a special ceramic and cooled with air passed through the discs and out of a series of precise holes in the blade.

Source: Rolls-Royce Holdings plc

Latest from Aerospace Manufacturing and Design

- UPCOMING WEBINAR: Additive Manufacturing for Aircraft Cockpit Interior Components

- Still time to register for the May 16 Manufacturing Lunch + Learn

- NIAR to add electric aircraft test capability

- Arnold Magnetic Technologies' custom electromagnetic capabilities

- Garmin earns best supplier recognition from Embraer for 9th consecutive year

- Dillon Manufacturing's Carbinite coating

- #43 Manufacturing Matters - 2024 Spring Aerospace Industry Outlook with Richard Aboulafia

- US operator UrbanLink orders 20 Lilium Jets