©MAPAL

In Vigneux-de-Bretagne on the outskirts of Nantes, one of MAPAL’s four sites in France, a dozen employees have been permanent members of the Global Organization for Assembly (GOA) since January 2024. If they need support, they can rely on the complete organization of MAPAL France with a total of 120 employees. Laurent Benezech, business development manager, Aerospace, is responsible for the GOA and works closely together with plant manager Thomas Dauteuille.

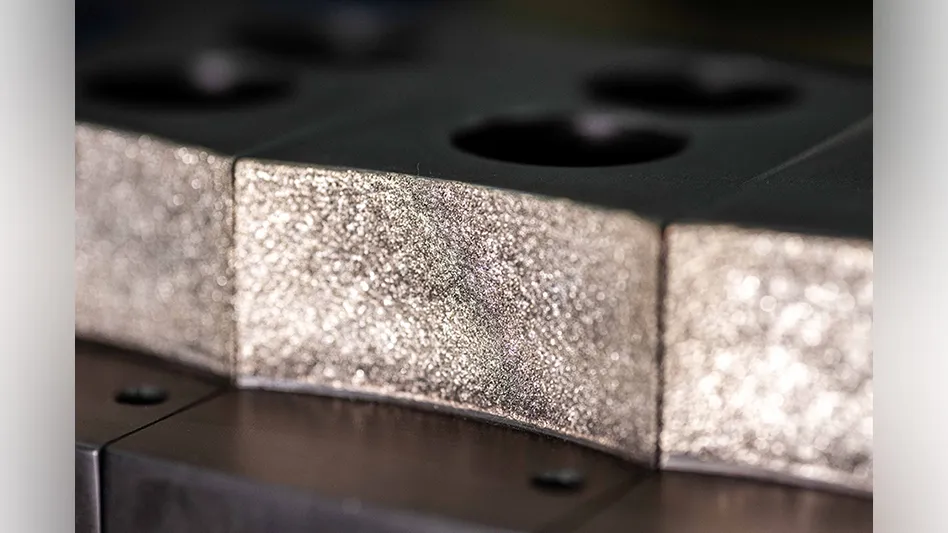

Boring and reaming tools for through-bores

with special cutting edges and guide

elements for the reliable production of

precise bores with high surface quality

and exact concentricity.

The GOA is MAPAL’s first Center of Competence outside Germany. “It’s very important for the development of the MAPAL Group to pool our expertise close to our strategic customers,” explains Christophe Potier, CEO of MAPAL France. He has played a major role in the company's success in the final assembly sector. During the 2009 financial crisis, he searched for new markets and was given the opportunity to find out about the requirements of aircraft assembly at Airbus. After visiting the site, he concluded that although there was great potential, MAPAL didn’t yet have the right products for it. Adapted tools were developed within one month and successfully tested on site, putting MAPAL in business. With the additional takeover of a small French tool manufacturer, the company also became a strategic supplier.

Around a million bores [holes] have to be drilled to assemble the parts of an airplane. The challenge is that the components are made of layers of different materials such as titanium, aluminum, and carbon fiber reinforced plastic (CFRP) in various combinations. As a result, there’s no standard range for machining rivet bores. MAPAL primarily provides solid carbide tools for this: step drills with sharp cutting edges and multi-bladed reamers. Great importance is attached to suitable coatings, which MAPAL is constantly further developing.

sinks and flat surfaces on pre-drilled bores.

MAPAL is highly successful with its assembly tool technologies and now boasts a large number of customers in the aviation industry. The new organizational structure is heavily tailored to the requirements of the sector.

“We have to be able to react very quickly. This has been a major challenge for MAPAL so far and the reason for our new organizational unit,” explains Piotr Tyczynski, global head of segment management Aerospace at MAPAL. “And just as important as having the right solutions is a good, tightly knit network to get the tools to our customers quickly and to support them in using them.”

Tools for drilling with a hand drill in multi-

layer composites (stacks) made of CFRP,

aluminum, high-alloy steels, or titanium.

Development, production, and customer service

The required capabilities were concentrated and expanded in France. The GOA acts as a sales organization that centrally handles all quotation processing worldwide for the final assembly division. In Vigneux-de-Bretagne, a development department has also been set up for testing customized tools. In addition to measuring all parameters, it’s also possible to adjust the tools to the customer's individual machining conditions. This is important because the many bores on the aircraft are drilled using semiautomatic or manual machines. Production is only a few meters away from the development department. If modifications need to be made to a tool, this is done within a few minutes and the tests can continue. Solutions can thus be developed in a very short amount of time. In addition, the GOA’s manufacturing unit also produces the first tool series and standardizes their production to ensure reproducibility in the Center of Competence Altenstadt and in Toulouse, as well as at all MAPAL production sites.

Experience and findings from France are shared with other MAPAL Group sites through the GOA. MAPAL appoints a process expert in each country because on-site support for customers is so important in the assembly field. These experts already exist in the key focus markets and form a network under the leadership of Thomas Dauteuille. Where the relevant knowledge still needs to be built up locally, customers receive centralized support from the GOA.

Latest from Aerospace Manufacturing and Design

- GrindingHub: a showcase for international grinding technology

- FLIR's Si2-Series of acoustic imagers

- Bell reveals Aircraft Laboratory for Future Autonomy

- Autogrip Machinery’s SP-324 stationary three-jaw chuck

- Sierra Space Dream Chaser reaches pre-flight testing milestone

- ABB's modular large robot portfolio

- #35 Lunch + Learn Podcast - How to use Autodesk Fusion with TATA Technologies

- UPCOMING WEBINAR: Additive Manufacturing for Aircraft Cockpit Interior Components