Norsk Titanium US Inc., Plattsburgh, New York – an additive manufacturing of aerospace-grade titanium components, announced production deliveries of new Boeing 787 Dreamliner components to Leonardo’s Grottaglie Plant, based in South Italy and part of Leonardo’s Aerostructures Division. This delivery adds a third production customer to Norsk’s growing commercial aerostructures customer base and represents Norsk’s first recurring production order from a European Union-based aerospace company.

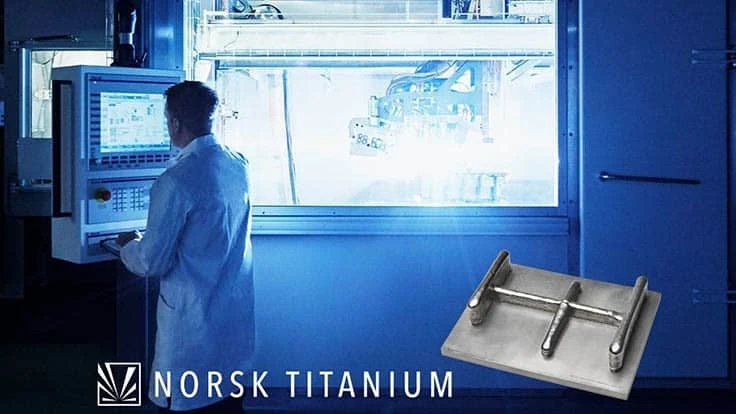

Using Norsk’s Rapid Plasma Deposition (RPD) process, Norsk engineers designed Ti-6Al-4V preforms that reduced raw material needs by 40%. Leveraging the RPD industrial process enabled Norsk to create a near-net-shape design, while maintaining the stringent process control and material properties needed for structural applications in Boeing aircraft.

“We are pleased to be Leonardo’s supplier,” said Karl Fossum, director of customer programs for Norsk. “This delivery marks a significant increase in the number of additively manufactured parts previously manufactured from titanium plate. It also is an important step towards our mission to provide an alternative to titanium forgings in aerospace applications.”

Norsk Titanium supplies aerospace-grade, additive manufactured, structural titanium components made by its patented Rapid Plasma Deposition (RPD) process that transforms titanium wire into complex components suitable for structural and safety-critical applications. RPD is the world’s first FAA-approved, 3D-printed, structural titanium, delivering substantial lead-time and cost savings for aerospace, defense and commercial customers.

Norsk Titanium is a Tier 1 supplier to Boeing, Spirit AeroSystems, and GKN and is committed to cost-reducing aerostructures and jet engines for the world’s premier aerospace manufacturers.

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools