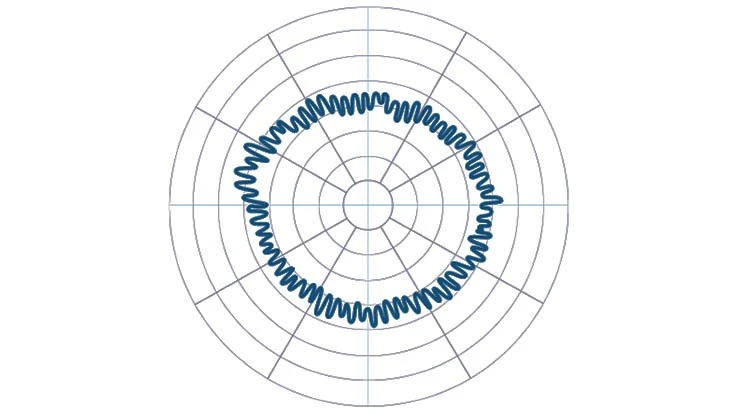

Measuring vibration on precision grinding machines

Vibration analysis equipment helps manufacturers reduce part rejection, improve productivity, and minimize machine down-time.

Modern CNC grinders are designed to minimize vibrations with advanced software that evaluates factors such as dynamic and static stiffness. Spindles, slides, ways, and other components are built to stringent specifications to increase rigidity and improve vibration. Despite machine design advancements, grinding is becoming more difficult for industries such as aerospace. Find out how they are coping by following the story in the digital edition.

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools