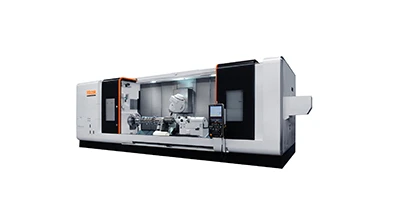

At IMTS 2012, Mazak introduces its Integrex e-670H-II, a high productivity solution for processing large, complex shaft-type components used by several industries, including aerospace, construction machinery, energy and marine.

The Integrex e-670H-II offers full, simultaneous 5-axis machining, allowing it to cut parts with tapered holes, blisks and spiral beveled gears in one setup. The machine falls within Mazak’s done-in-one concept because it incorporates all machining processes from raw material input through final machining. As such, the Integrex e-670H-II delivers extremely fast in-process time as well as reduces in-process inventory.

For efficient 5-axis machining, the Integrex e-670H-II includes a powerful 1,600rpm, 60hp (45 kW) spindle for turning and 360° C-axis control. It also has a #50-taper, 50hp (37kW), 10,000rpm integral motor milling spindle that rotates 240° in the B-axis.

A standard 40-tool magazine for storage and retrieval of turning, milling, drilling, and tapping tools further supports the machine’s multi-tasking processes, and its fast automatic tool changer helps reduce non-cut times. Businesses with higher machining requirements will benefit from the optional 80- and 120-tool magazines. Also, the tool magazines and automatic tool changer can accommodate a 40” long boring bar.

A standard 40-tool magazine for storage and retrieval of turning, milling, drilling, and tapping tools further supports the machine’s multi-tasking processes, and its fast automatic tool changer helps reduce non-cut times. Businesses with higher machining requirements will benefit from the optional 80- and 120-tool magazines. Also, the tool magazines and automatic tool changer can accommodate a 40” long boring bar.

The Integrex e-670H-II offers a maximum machining diameter of 42.13” (1,070mm) and a generous Y-axis stroke of 26.37” (670mm) for accommodating large-diameter chuck parts with maximum weights of up to 13,228 lb (6,000kg). To increase long, shaft-type part holding accuracy and rigidity, Mazak equipped the machine with a heavy-duty NC tailstock that provides easy set up as well.

Mazak’s MX Hybrid Roller Guide System on the Integrex e-670H-II delivers levels of durability and reliability that result in long-term accuracy. The Mazak MX Hybrid Roller Guide System increases vibration dampening, extends tool life, handles higher load capacities, and eliminates tramp oil in the coolant by utilizing a greener grease-based lubrication system.

To further reduce machining processes and improve machining capability, the Integrex e-670H-II integrates with a wide variety of optional equipment, including a long boring bar system for the deep machining of inner diameters of large workpieces, a U-Axis tool for machining complex workpiece features, and a rigid tool holder system with four clamping units for increasing the machine’s range of applications.

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools