Photo courtesy of LAMBDA research

Although improvements in AM are continuously being made, AM parts generally aren’t used in fatigue-critical applications. Surface enhancement processes which impart compressive residual stresses have a significant improvement on conventionally manufactured components.

This study explores the possibility of improving the fatigue properties of AM Inconel 718 superalloy components with these same surface enhancement processes.

Challenge: A gap in durability

AM components may not provide the fatigue performance of conventionally manufactured components. The fatigue strength of AM components can be negatively affected by increased surface roughness, internal defects, and tensile residual stress.

Solution: Compressive residual stress

of Inconel 718 test samples.

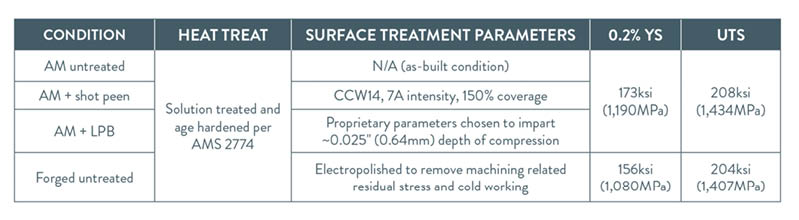

Compressive residual stress was applied to AM Inconel 718 test samples. Two different methods were used: shot peening and low plasticity burnishing (LPB). Surface treatment parameters along with heat-treat and material property data are listed in Table 1 (pg.20) for all conditions studied.

Test samples were made using a laser powder bed fusion (LPBF), a well-established AM process that builds a geometry sequentially layer-by-layer using a laser heat source on a powder bed. Samples were built on a plate using a raster build pattern (parallel lines drawn back and forth across a build layer) and later removed from the build plate via wire-cut electrical discharge machining (EDM). Prior to shot peening and LPB processing, the samples were subjected to a solution heat treatment and age hardening as required by the ASM 2774 standard.

High-cycle fatigue and residual stress measurements were performed to evaluate the effectiveness of each condition and solution.

Results: Surface treatments increased AM material life roughly 10x

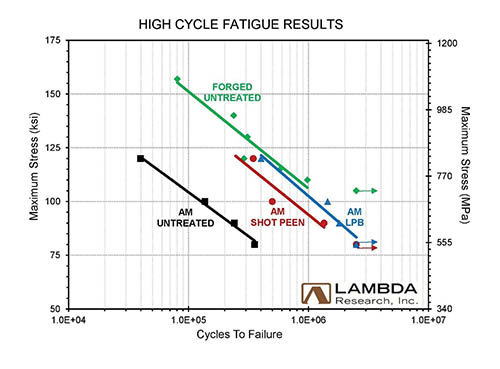

High-cycle fatigue tests were performed at room temperature under constant amplitude loading; results shown in Figure 2. Arrows indicate a run-out condition in which the specimen didn’t fail. The fatigue life for the AM untreated condition was approximately 10% of the conventionally forged condition. Both LPB and shot peening significantly improved the fatigue properties of the AM material with LPB producing the largest gains. LPB-treated AM material fatigue properties approached that of the forged condition.

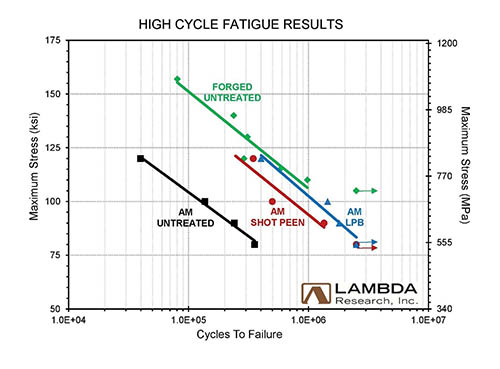

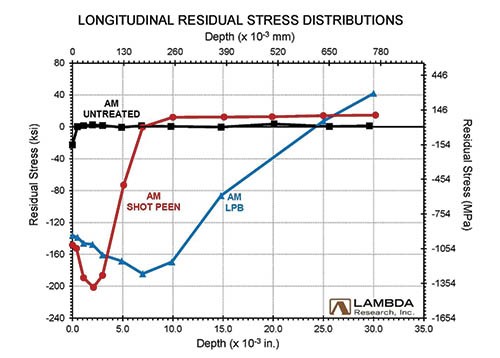

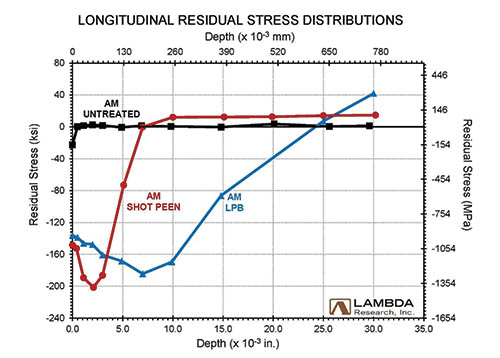

Residual stress distributions are shown in Figure 3. The AM baseline material had relatively low levels of residual stress after heat treatment. Shot peening and LPB introduced relatively high magnitude compression. LPB introduced a depth of compression about 3x that of shot peening.

Test results on surface treated AM Inconel 718 reveal that imparting compressive residual stress significantly extends fatigue life, even approaching the fatigue life of traditionally forged material.

This study indicates residual compression may allow AM components to be considered for fatigue-critical applications. By including mechanical surface enhancement and engineered compressive residual stress in the manufacturing process of AM parts, acceptable levels of fatigue performance may be achievable.

Lambda Research Inc.Latest from Aerospace Manufacturing and Design

- Upcoming webinar to highlight the rise of electric vehicles

- JEKTA, ZeroAvia partner on hydrogen-electric amphibious aircraft

- Mastercam 2025 software

- IMTS 2024 Conference: Cutting Edge Innovations: Maximizing Productivity and Best Practices with Superabrasives

- Eve Air Mobility unveils first full-scale eVTOL prototype

- Dillon Manufacturing's Fast-Trac Jaw Nuts

- IMTS 2024 Conference: Breaking the Tradeoff: Utilizing Deep Learning AI with X-ray Computed Tomography for Unparalleled Clarity and Speed

- #47 - Manufacturing Matters - The Ins and Outs of CMMC 2.0 with Smithers Information Security Services