Haas Automation’s new Through-Tool Air Blast system provides high-pressure/high-flow air through the cutting tool to clear chips during dry machining. The system uses an all-new bearingless union that allows either air or coolant to be transmitted through the spindle to the tool. Because the Air Blast system uses the same plumbing as the Through-Spindle Coolant (TSC) system, the operator can easily switch between the two, based on their machining requirements.

Like through-spindle coolant, the Haas Through-Tool Air Blast cools the cutting edge of the tool, while also clearing chips from pockets to prevent recutting. Additional benefits include:

• Improved dry machining performance

• Faster chip removal

• Improved surface finish

• Longer tool life

• Cleaner machine

• Zero coolant usage and disposal

• Machine can still utilize Through-Spindle Coolant (TSC)

Available soon on most Haas 40-taper VMCS, the Through-Tool Air Blast system also requires the Through-Spindle Coolant option. Air requirements are dependent upon application and tooling.

Latest from Aerospace Manufacturing and Design

- America Makes announces two project calls worth $8 million

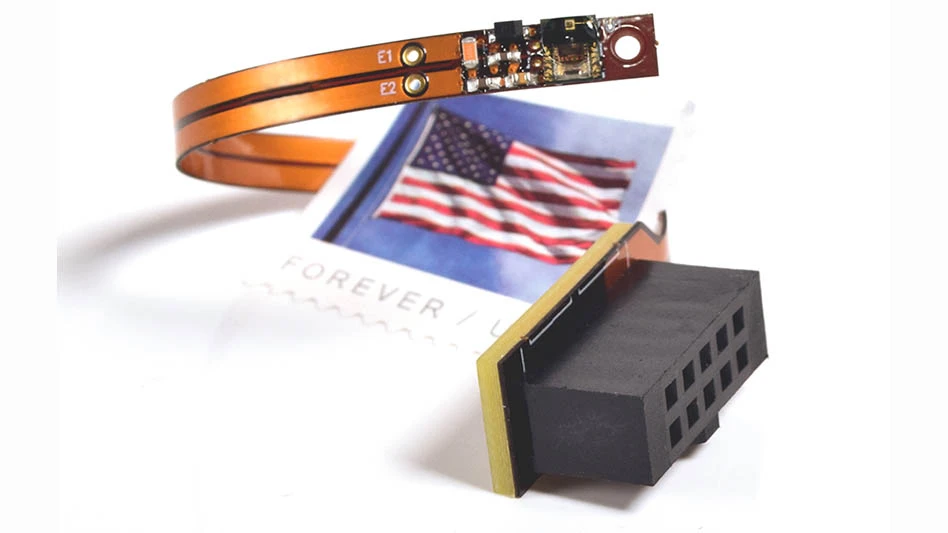

- Jaw force gauges

- Air India orders 30 Boeing 737 MAX jets

- Speed increasers for lathes, Swiss-style machines

- #81 Manufacturing Matters - Additive Manufacturing Analysis, Trends, Forecasts with Terry Wohlers

- A look at the latest in the defense industry

- Workholding Roundtable to feature expert insights on a booming market

- OnRobot to host Build Your Automation Roadmap event