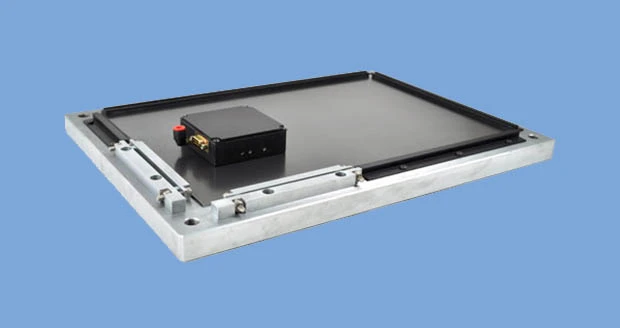

Santa Clarita, California – H2W Technologies’ dual axis linear stepper motors are for open loop positioning applications requiring 2-axis motion in a single plane. They can perform at speeds of up to 80ips [2m/sec] and strokes of up to 20" x 30" [0.5m x 0.75m].

Linear stepper motors are capable of very precise position, velocity, and acceleration control when coupled with a micro-stepping drive and indexer.

The moving assembly called the forcer is supported by magnetically preloaded air bearings that are embedded in the active surface of the forcer. The bearings are designed to support the customer’s payload and to maintain the required 0.0005" to 0.0010" [12µm to 25µm] gap between the platen and the forcer.

The step and direction signal for each axis comes from two separate micro-stepping drives (2- or 4-phase). A 2-axis indexer is required to send step and direction signals to the drivers. For 2-phase motors, the full step is 0.010" [250µm] and for 4-phase motors the full step is 0.005" [125µm]. With micro-stepping, resolutions in the order of 0.5µm to 1µm are achievable.

The dual axis linear stepper motor is a complete, 2-axis, single-plane, air bearing positioning system with the motor, the bearings, and the positioning system all built into one compact package. Integrating linear encoders with the stepper motor allows for a hybrid, closed-loop positioning system.

Advantages:

- Low profile and small cross section

- High Speed

- No servo tuning required

- Multiple forcers on a single platen

Applications:

- Pick and Place

- Wire bonders

- Parts transfer

- Fiber optic

Source: H2W Technologies Inc.

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools