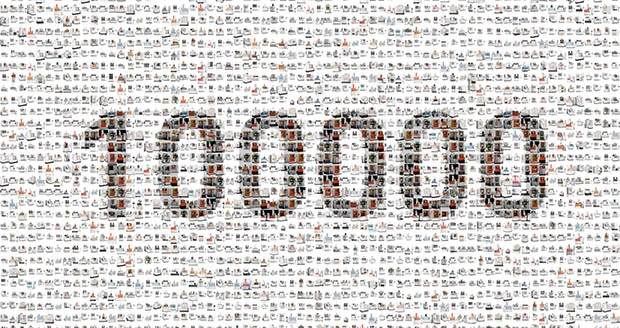

Lincolnshire, Illinois – In June, GF Machining Solutions secured a major company milestone when its tally of global machine installations reached 100,000. This number includes machines from the company’s comprehensive portfolio of milling, electrical discharge machining (EDM), and laser texturing product families.

GF Machining Solutions has a far reaching legacy, including Mikron AG’s introduction of the first rounding up tool for fine wheels in 1910, Charmilles’ development of the world’s first industrial EDM in 1954, and Agie’s development of the AGIETRON A4 with a pneumatic servo drive for the Z-axis, also in 1954.

With the introduction of more than 900 machine types, the company’s long history encompasses a diverse list of industry accomplishments, including:

- First universal machining center

- First numerical control wire EDM machine

- First automatic wire-threading solution

- First milling machine with a direct drive on all axes

- First milling machine family with an automatic tool changer and fully enclosed work area

- First standardized numerical control for wire and die-sinking EDM machines

- First true high-speed machining center

- First robot integrated on a die-sinking EDM machine

- Development of iQ technology for minimized electrode wear

- World’s largest and most affordable laser texturing machine

This ongoing commitment to innovation has brought GF Machining Solutions to where it stands today, with more than 100,000 of its machines operating in manufacturing facilities around the world. This includes approximately 65,000 machines in Europe, 20,000 machines in the Americas, and 15,000 machines in Asia.

Source: GF Machining Solutions

Latest from Aerospace Manufacturing and Design

- The power of the plasma pen: Revolutionizing adhesion in aerospace manufacturing

- Mazak will show shops how to drive production at Dallas Open House

- Heavy-duty pneumatic flex locators

- Tacky Tape vacuum bag sealing tapes for aerospace composites continue a legacy

- Embraer’s Phenom 300 series is best-selling light jet for 14th consecutive year

- Expanded PushPull connector portfolio

- AEC is Meltio’s official sales partner

- Coolant-thru options for straight, 90-degree, universal live tools